.png)

.png)

.png)

Welding is a diverse field with multiple techniques, each offering unique advantages and drawbacks. Among these, Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW) are two of the most widely used methods in arc welding. Understanding the differences between them is crucial for selecting the right process for your projects.

Before diving into the specifics, here’s what you should know:

In this guide, we will cover the processes, advantages, and disadvantages of both GMAW and FCAW, compare them in a detailed analysis, and briefly touch on their comparison with SMAW (Shielded Metal Arc Welding).

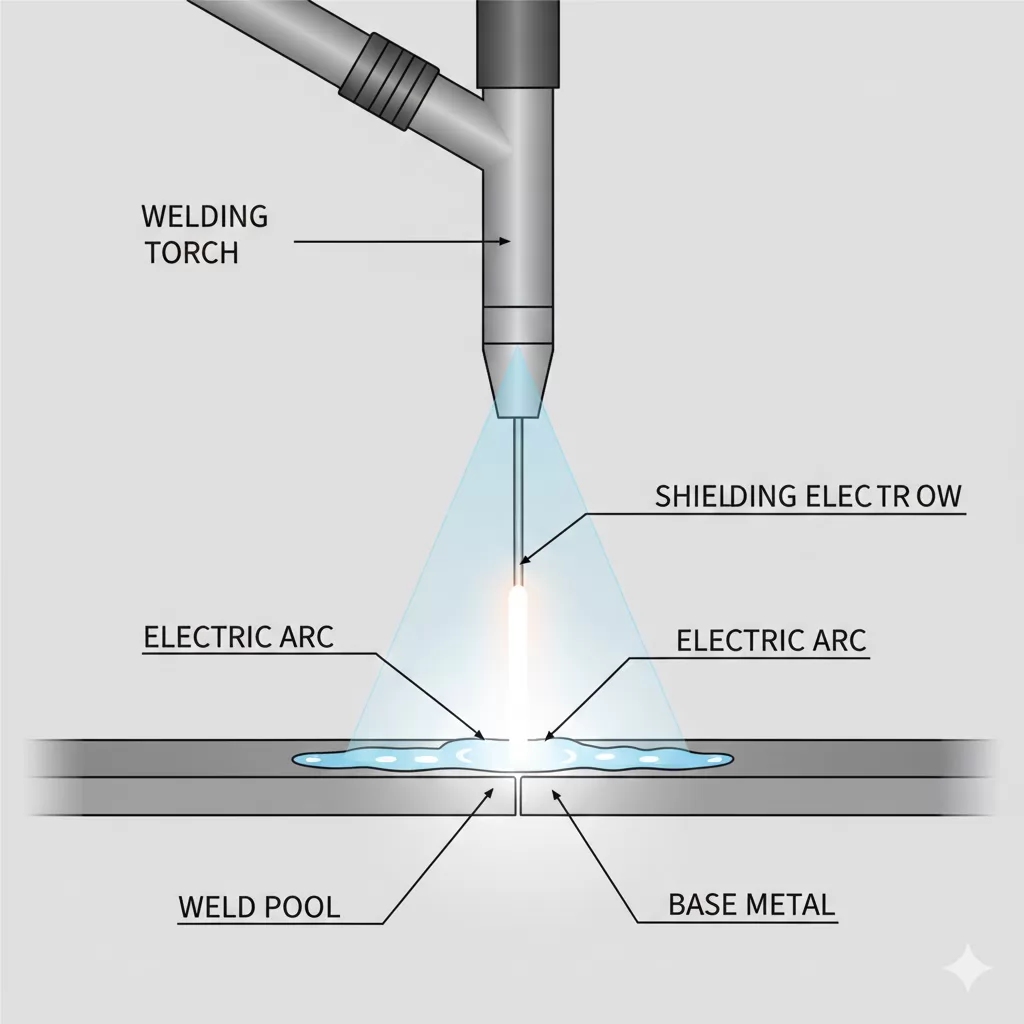

Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding, is a widely used welding technique due to its speed, versatility, and ease of use. It is commonly applied to steel and alloy materials and can be performed in automated, semi-automated, or manual modes.

GMAW was initially developed in the 1940s for aluminum and other non-ferrous materials. Later, it became popular for steel welding, especially after active gas mixtures like carbon dioxide and argon-carbon dioxide blends were introduced, reducing costs and increasing efficiency.

The GMAW process uses a continuous solid wire electrode fed through a welding torch, shielded by inert or active gas to protect the weld pool. Key components include:

The welder must maintain uniform voltage and wire feed speed for consistent weld quality. GMAW is suitable for welding materials such as:

GMAW offers a range of advantages, making it suitable for various industries due to its affordability, efficiency, and weld quality. Here are the main advantages:

GMAW is efficient at higher speeds, and its initial setup cost is lower compared to other welding methods. The process allows the use of different gas mixtures, reducing the reliance on expensive argon. Continuous wire feed simplifies operation and reduces labor effort, while automation further increases productivity. It can replace other processes like resistance welding, riveting, silver soldering, and brazing in many applications.

The equipment is easy to set up and operate. Welders only need to manage the torch angle, electrode stick-out, weld pool, and travel speed. This makes GMAW faster and more consistent than some other welding techniques.

GMAW produces minimal distortion because it uses solid wire electrodes. Less spatter and slag means a smoother finish and reduced post-weld cleaning costs. Fume and heat production are lower compared to other welding types, making it safer and more cost-efficient.

This method is not limited to a single position or material. It works on light and heavy materials and allows higher current concentration, which improves penetration. Adjustments in groove angle and root face thickness reduce filler buildup and preparation time.

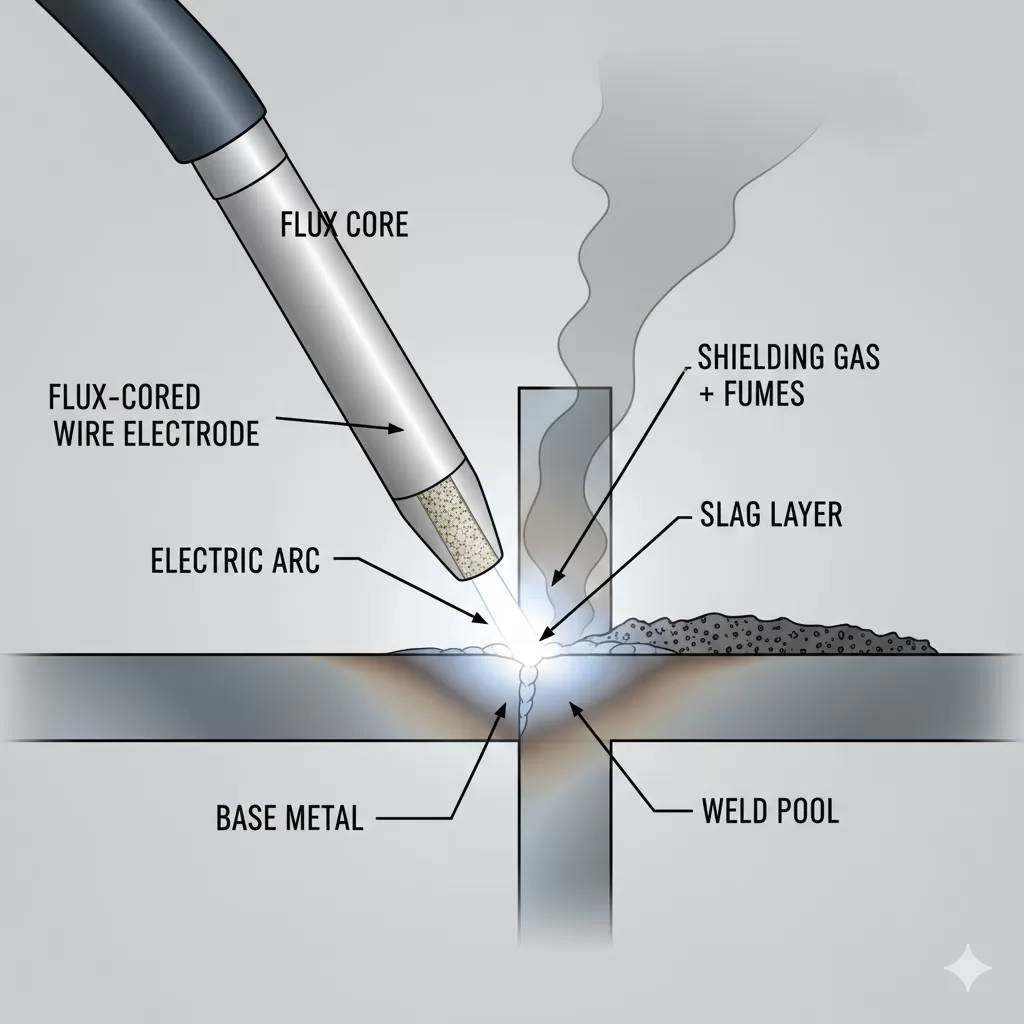

Flux-cored arc welding (FCAW) is also known as dual-shield welding. It shares several advantages with GMAW and uses similar equipment, but it employs a hollow, flux-filled tubular electrode instead of a solid wire. FCAW can operate with or without an external shielding gas.

FCAW uses the heat generated by an electric arc to fuse materials. There are two methods:

This method uses external shielding gas (usually CO2 or a CO2/argon mix) to protect the weld from contamination. It is ideal for welding structural steel and thicker materials. The process produces smoother welds with fewer defects.

In this method, the flux-filled electrode generates its own shielding gas and forms slag over the weld. It is suitable for outdoor welding in windy conditions and reduces preparation time.

GMAW and FCAW are two popular arc welding processes, each with its own strengths and weaknesses. The table below summarizes the key differences:

| Attributes | GMAW | FCAW |

|---|---|---|

| Shielding Gas | Operates with external shielding gas only | Can operate with shielding gas (dual-shield) or self-shielding without gas |

| Electrode | Solid wire electrode | Flux-cored tubular wire electrode |

| Best for | Indoor, cleaner applications | Outdoor, thick, or dirty/rusty materials |

| Welding Speed | Medium speed, precise work | High speed, ideal for industrial production |

| Material Thickness | Thin to medium materials | Medium to thick materials |

| Cost | Higher due to gas consumption | Overall lower, less gas needed (self-shielding) |

| Ease of Use | Beginner-friendly for clean, simple projects | More complex; requires slag removal |

| Portability | Limited due to gas cylinders | Highly portable, especially self-shielded method |

| Appearance | Clean, smooth welds | Slag must be removed; slightly rougher finish |

Here’s a detailed comparison between Gas Metal Arc Welding (GMAW) and Shielded Metal Arc Welding (SMAW):

| Attributes | SMAW | GMAW |

|---|---|---|

| Welding Process | Flux-coated electrode produces its own shielding gas | Continuous wire electrode with external shielding gas |

| Shielding Gas | Electrode coating produces shielding gas | Requires external shielding gas like CO₂ or Ar mix |

| Portability | Highly portable | Limited portability |

| Ease of Use | Simple setup, suitable for beginners | Requires more equipment, precise control needed |

| Material Suitability | Thick, dirty, or rusty materials | Thin to medium-thickness materials |

| Applications | Outdoor, repair, and construction sites | Indoor, clean, and controlled projects |

| Weld Appearance | Slag removal required after welding | Clean, smooth welds |

| Speed | Slower due to manual electrode | Medium speed, precise output |

Comparison between Shielded Metal Arc Welding (SMAW) and Flux-Cored Arc Welding (FCAW):

| Attributes | SMAW | FCAW |

|---|---|---|

| Welding Process | Flux-coated electrode produces shielding gas | Constant-fed flux-cored wire electrode |

| Shielding Gas | Flux coating provides gas | Dual-shield: can use external gas or self-shielding |

| Portability | Highly portable | Portable, but wire feeder required |

| Ease of Use | Simple setup, beginner-friendly | More complex; requires slag removal |

| Material Suitability | Thick, dirty, or rusty materials | Clean and rusty surfaces, thick materials |

| Applications | Repair, construction, maintenance | Industrial applications, heavy fabrication |

| Cost | Low, minimum equipment required | Higher due to equipment and wire costs |

| Speed | Slower, manual electrode operation | Faster, suitable for high-production projects |

| Post-Weld Cleaning | Requires extensive slag removal | Slag removal needed but less extensive |

Choosing the right welding method depends not only on material and thickness but also on the work environment, production speed, and desired weld quality. Each welding technique offers unique advantages for specific applications.

SMAW, also known as stick welding, is widely used in construction, maintenance, and outdoor repair work. Its portability and ability to handle dirty or rusty materials make it ideal for field work where controlled environments are not available. Common applications include bridge construction, pipeline repair, and shipbuilding maintenance.

GMAW, or MIG welding, is preferred in industrial and production environments due to its consistent weld quality and clean finish. It is commonly used for automotive manufacturing, metal furniture production, and fabrication of thin to medium-thickness steel and aluminum components.

FCAW is highly suitable for heavy fabrication and industrial projects where high deposition rates are required. Dual-shield FCAW provides excellent weld penetration on thick sections, making it popular in structural steel construction, shipbuilding, and large-scale manufacturing operations.

TIG welding, known for precision and high-quality welds, is ideal for thin materials and critical applications where weld appearance matters. It is commonly applied in aerospace, food processing equipment, and artistic metalwork, where clean and precise welds are essential.

Selecting the most suitable welding technique can save time, reduce costs, and improve the overall quality of your projects. Here are some essential tips to consider:

Even experienced welders can face challenges if proper precautions are not taken. Avoiding these common mistakes will improve weld quality and safety:

Choosing the right welding process is crucial for ensuring high-quality welds, efficiency, and safety. Each technique has its own strengths and limitations:

When selecting a welding method, consider material type, environment, production speed, equipment availability, and desired weld quality. Avoid common mistakes such as using the wrong electrode, neglecting surface preparation, or improper parameter settings.

Understanding the differences between GMAW, FCAW, and SMAW allows welders to choose the most suitable method for their project, optimize efficiency, and achieve durable, clean, and precise welds.