.png)

.png)

.png)

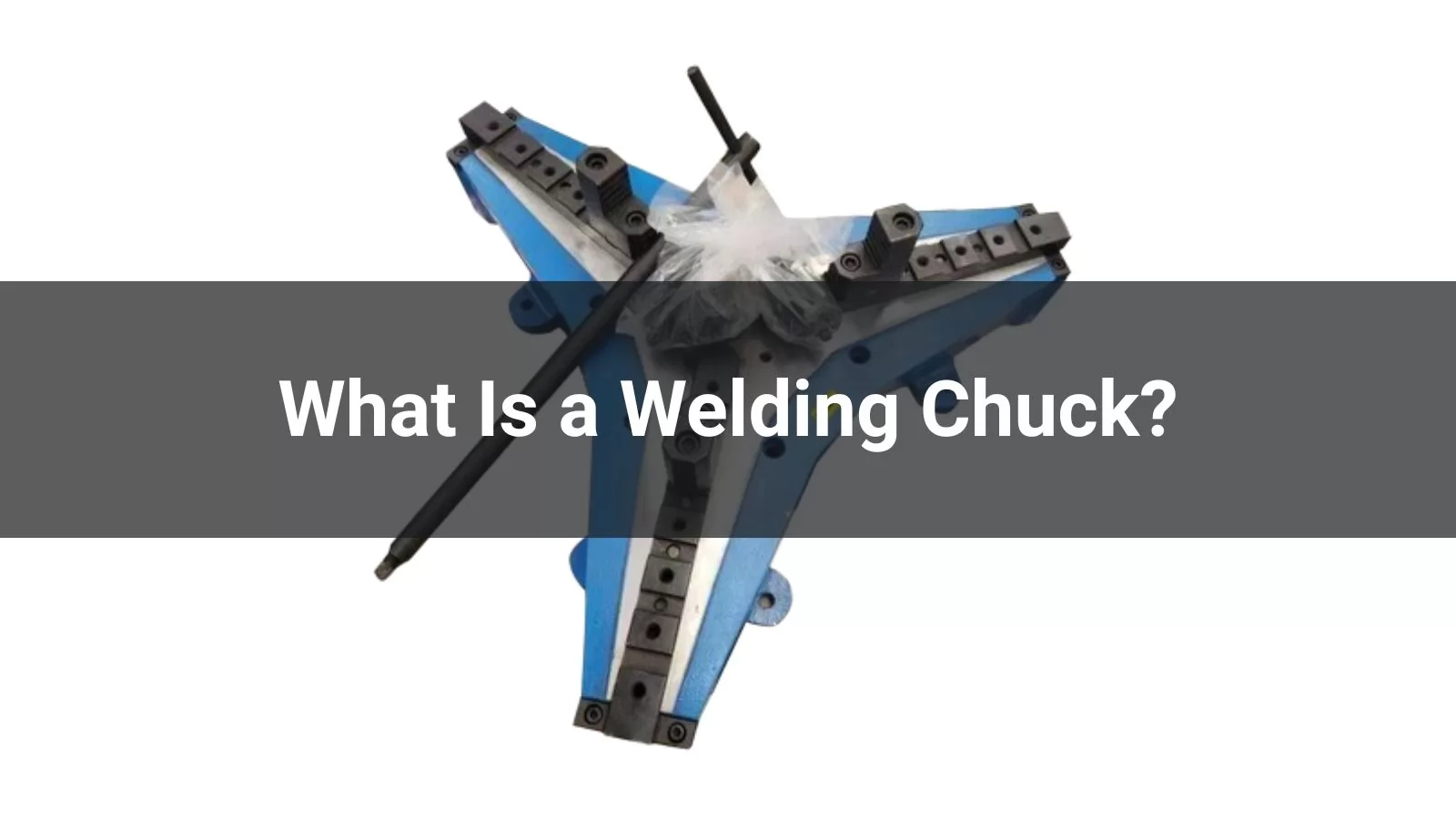

Wondering how a simple welding chuck can boost your production efficiency by 30%? A welding chuck, also known as a welding gripper or positioner chuck, is a specialized rotating clamp—often a 3-jaw self-centering type—designed to hold and position workpieces securely during welding. Unlike broader welding fixtures that focus on static holding, a welding chuck emphasizes rotational stability for precise alignment, minimizing deviations and enhancing weld quality. This tool is vital in automotive manufacturing, aerospace engineering, pipe welding, and mechanical processing, where high-precision welds are essential for safety and performance.

A welding chuck is a mechanical device, typically a rotating gripper like the 3-jaw self-centering model, used to secure and position workpieces during welding operations. It differs from a general welding fixture, which provides static support, by enabling rotation for optimal weld access—ideal for pipes and cylindrical parts. Its primary functions include:

Applications span automotive body assembly, aerospace structures, pressure vessels, pipe welding, and general mechanical manufacturing. For instance, in pipe fabrication, 3-jaw chucks ensure uniform clamping for high-volume production.

Welding chucks vary by operation and application, with the 3-jaw self-centering type being the most common for rotational precision. Here's an overview:

| Type | Advantages | Limitations | Applications |

|---|---|---|---|

| Manual | Low cost, simple operation | Low efficiency for high-volume | Small-batch production, custom fittings |

| Pneumatic/Hydraulic | Fast, consistent clamping; high force | Requires power source | Automated assembly lines, heavy-duty like aerospace |

| 3-Jaw Self-Centering | Automatic centering, 30% efficiency gain | Limited to cylindrical shapes | Pipe/tube welding, high-volume fabrication |

| Magnetic | Quick for complex shapes | Only magnetic materials | Irregular workpieces in fabrication |

| Custom (e.g., 4/6-Jaw) | Tailored precision | High design cost | Automotive, aerospace specifics |

The structure of a welding chuck ensures durability and precision. Key elements include:

Workflow: 1. Base setup → 2. Insert positioning pins → 3. Clamp jaws → 4. Rotate for welding. For visuals, see 3-jaw chuck demo.

Welding chucks enhance weld uniformity and reduce misalignment, directly improving product quality. In automotive, they enable precise car body assembly; in aerospace, they handle complex structures. They support automation, replacing multiple jigs to cut costs by up to 40% (e.g., one flexible chuck vs. 9 dedicated ones). Sustainability benefits include aluminum welding for lightweight EVs, reducing CO2 emissions by 13% per 50kg saved.

In Industry 4.0, chucks integrate IoT sensors for real-time force/temperature monitoring and adaptive control. A leading automotive firm using sensor-equipped 3-jaw chucks achieved 30% welding efficiency gains via automated feedback. By 2025, AI-adaptive chucks will enable predictive maintenance, further boosting uptime.

Flexible chucks (e.g., modular 3/4-jaw with quick-change bases) outperform traditional fixed ones in adaptability, suiting small-batch production amid Industry 4.0 demands. Traditional chucks remain cost-effective for high-volume standardization but lack versatility. Hybrid systems are projected to dominate 70% of small-batch by 2027, per market analyses, blending flexibility with precision.

| Aspect | Flexible Chucks | Traditional Chucks |

|---|---|---|

| Adaptability | High; reconfigurable for shapes/sizes | Low; fixed for specific tasks |

| Cost | Higher initial, 40% long-term savings | Lower upfront |

| Efficiency | 30% faster setup | Suited for mass production |

Challenges include thermal distortion, diverse shapes, and repeatability. Innovations like retractable pins and quick-change bases address these; e.g., Preston Eastin's designs reduced aerospace downtime by 25%. 3D-printed prototypes enable custom jaws for curved surfaces, enhancing precision.

Reliable chucks ensure durable welds, reducing automotive warranty claims by 20% (AWS data). In aviation, precise positioning means safer flights; for consumers, it translates to robust products like EV frames, enhancing trust and longevity.

1. What is the difference between a welding chuck and a machine tool chuck?

A welding chuck secures and rotates workpieces for welding (e.g., 3-jaw for pipes), while a machine tool chuck holds for machining like turning.

2. How do I choose the right type of welding chuck?

Based on volume, material, and automation—flexible for diverse/low-volume, specialized for mass.

3. What’s the difference between a welding chuck and a welding fixture?

Chucks focus on rotation/self-centering; fixtures on static holding/positioning.

4. Is a flexible welding chuck cost-effective?

Yes, higher initial cost but replaces multiple jigs, saving 40% long-term.

5. Can welding chucks be customized?

Absolutely, for specific parts like 6-jaw in automotive.

Updated September 2025: Welding chucks are indispensable for precision, efficiency, and safety in modern manufacturing. With Industry 4.0 advancements like AI-integrated flexible designs, they drive superior performance in automotive, aerospace, and beyond. Ready to upgrade? Download our free welding chuck checklist or explore options to enhance your production.