.png)

.png)

.png)

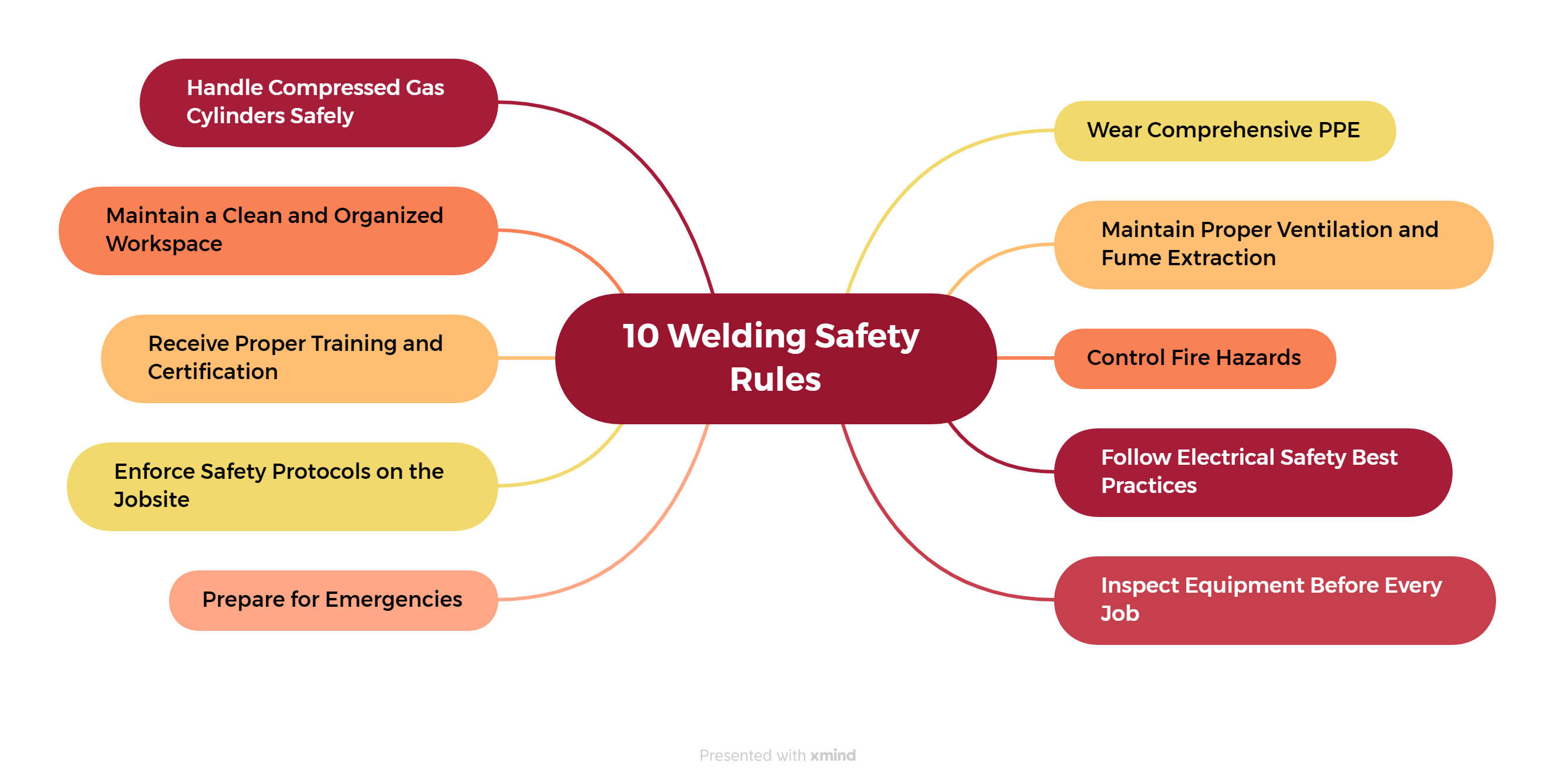

Welding is an indispensable process in industries such as manufacturing, construction, shipbuilding, and automotive repair. However, it involves significant hazards — from intense heat and ultraviolet radiation to toxic fumes and compressed gases. Understanding and following welding safety rules is essential not only to protect welders themselves but also to maintain productivity, ensure compliance with safety regulations, and safeguard the work environment. Below are the top 10 welding safety rules every welder should follow, supported by industry best practices and regulatory guidelines.

Welding PPE goes far beyond a helmet. It should protect your entire body from sparks, heat, UV radiation, and debris:

Welding fumes may contain hazardous substances such as manganese, lead, or hexavalent chromium. Long-term exposure can lead to respiratory disease or neurological damage. Always ensure adequate airflow in the workspace, and use fume extraction systems to remove contaminants from the breathing zone. Reference OSHA 1910.252 for ventilation requirements.

Fire safety is paramount in welding due to sparks and molten metal spatter. Key measures include:

Arc welding equipment carries the risk of electric shock, which can be fatal. Always ensure:

Daily inspection prevents equipment failure and accidents. Check:

Improper handling of compressed gas cylinders can lead to explosions or fire. Best practices include:

A cluttered work area increases the risk of trips, falls, and fires. Keep tools, materials, and cables organized. Ensure walkways are free from debris and flammable waste.

Professional training ensures welders are familiar with the hazards of their specific processes and equipment. Certification from recognized bodies such as the American Welding Society (AWS) not only improves safety awareness but also demonstrates professional competence.

Even the best rules are ineffective without consistent enforcement. Supervisors should conduct regular safety briefings, monitor compliance, and maintain clear signage to remind workers of critical safety procedures.

Emergency preparedness can mean the difference between a contained incident and a catastrophic accident. Every welding site should have:

Using high-quality positioning and rotation equipment can significantly improve welding safety. MISA welding positioners and rotators reduce the need for manual handling of heavy workpieces, minimizing strain injuries and improving access to weld joints. By stabilizing components at optimal angles, these devices also reduce the risk of accidental slips, burns, and poor-quality welds caused by awkward positions.

Welding safety is a shared responsibility. By following these ten essential rules — and integrating the right tools, training, and procedures — welders can significantly reduce risks while maintaining productivity and quality. Incorporating advanced equipment from manufacturers like MISA not only boosts efficiency but also supports a safer, more compliant work environment.