.png)

.png)

.png)

Welding is a craft that blends precision, safety, and creativity. For beginners, mastering the basics can feel overwhelming, but with the right guidance, you can build a strong foundation. This article dives into 10 essential welding tips tailored for newcomers, designed to spark your confidence and ignite your skills. Whether you're tackling MIG, TIG, or stick welding, these innovative insights will help you weld smarter, safer, and better.

Before you strike an arc, prioritize safety. Welding exposes you to intense light, heat, and sparks, so proper gear is non-negotiable. Invest in a high-quality auto-darkening helmet to shield your eyes from harmful UV rays. Wear flame-resistant clothing, including a welding jacket, gloves, and steel-toed boots. Ensure your workspace is well-ventilated to avoid inhaling harmful fumes. A beginner’s mistake is underestimating safety—don’t skip this step.

Pro tip: Check your gear for wear and tear before every session. A small hole in your glove could lead to burns or discomfort.

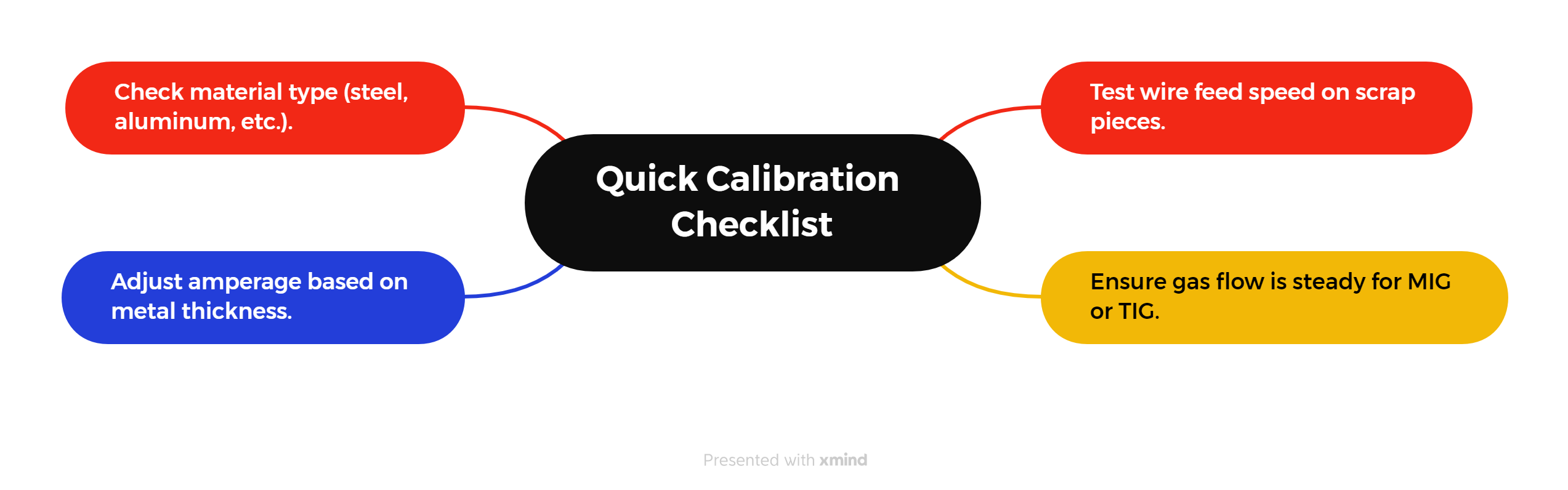

Every welding machine has its quirks. Whether you’re using a MIG welder for versatility or a TIG for precision, take time to read the manual and understand settings like voltage, wire speed, or amperage. Beginners often rush into welding without calibrating their equipment, leading to poor welds. Experiment with scrap metal to dial in the perfect settings for your project.

Unique angle: Create a “cheat sheet” for your machine’s settings based on material thickness and welding type. Keep it handy for quick reference.

A clean surface is the foundation of a strong weld. Remove rust, paint, oil, or dirt using a wire brush, grinder, or degreaser. Contaminants can weaken your weld, causing porosity or cracks. Beginners often overlook this, but a pristine surface can make or break your project.

Innovative twist: Try using a vinegar soak for rusty metal before brushing—it’s eco-friendly and effective for light rust removal.

Welding is as much about rhythm as it is about skill. Maintain a steady hand and consistent travel speed to create uniform beads. For MIG welding, practice a “push” or “pull” technique depending on your desired penetration. For TIG, focus on precise torch control and filler rod application. Stick welding demands smooth electrode movements to avoid slag inclusions.

Creative practice idea: Trace patterns on cardboard with a pen to simulate welding motions. This builds muscle memory without wasting materials.

The weld pool—the molten metal formed during welding—is your canvas. Too much heat can burn through thin materials, while too little can result in weak welds. Beginners should practice maintaining a consistent pool size by adjusting their torch angle (typically 10-15 degrees) and travel speed. Watch the pool’s behavior: a steady, circular pool indicates good control.

Unique tip: Visualize the weld pool as a small pond. Keep its “shores” even by moving steadily, avoiding ripples from erratic motion.

| Issue | Cause | Fix |

|---|---|---|

| Irregular pool shape | Inconsistent speed | Practice steady hand movements |

| Burn-through | Excessive heat | Lower amperage or increase speed |

| Poor fusion | Low heat or fast travel | Increase amperage or slow down |

Selecting the correct filler material is critical for strong welds. For example, use ER70S-6 wire for MIG welding mild steel or 4043 filler for aluminum TIG welding. Beginners often grab any filler without checking compatibility, leading to brittle welds. Always match your filler to the base metal’s composition and thickness.

Pro insight: Store filler rods in a dry, sealed container to prevent oxidation, which can compromise weld quality.

Don’t dive into your dream project right away. Practice on scrap metal to hone your skills and build confidence. Try different joint types—butt, lap, or T-joints—to understand how welds behave. Mistakes on scrap are learning opportunities, not costly errors.

Creative exercise: Create a “weld journal” to track your practice sessions, noting settings, techniques, and results for future reference.

Understanding weld imperfections like porosity, undercut, or spatter helps you troubleshoot issues. For instance, porosity (tiny holes in the weld) often results from dirty surfaces or improper gas flow. Undercut (grooves along the weld) may stem from excessive heat or incorrect torch angle. Keep a mental or physical checklist of common flaws and their fixes.

Innovative approach: Take photos of your welds and compare them to online weld imperfection guides to self-diagnose issues.

Your welding environment impacts your results. Ensure your workspace is clutter-free, well-lit, and equipped with a sturdy welding table. Use clamps or jigs to secure your workpiece, preventing movement during welding. Good lighting helps you see the weld pool clearly, reducing errors.

Unique hack: Use magnetic welding holders to position metal pieces precisely, saving time and improving accuracy.

Welding is a lifelong learning journey. Join online forums, watch tutorials, or take a local welding class to expand your knowledge. Experiment with new techniques, like weaving for wider welds or pulsing for TIG precision. The more you explore, the more versatile you’ll become.

Engaging tip: Follow welders on platforms like X to see real-time projects and tips from pros and hobbyists alike.

Connect with other welders to share tips, troubleshoot problems, and find inspiration. Local welding shops, online groups, or social media communities are great places to start. Beginners often feel isolated, but a supportive network can accelerate your growth.

Actionable idea: Start a welding log on a platform like X, posting your progress and asking for feedback from experienced welders.

Becoming a skilled welder takes time, patience, and practice. By prioritizing safety, mastering your tools, and embracing continuous learning, you’ll transform from a beginner to a confident welder. Use these 10 tips as your roadmap, and don’t be afraid to experiment and make mistakes. Every weld is a step toward mastery. Start small, stay safe, and let your creativity shine through your work.

Ready to start welding? Grab your gear, practice these tips, and share your progress with the welding community. Have a favorite tip or trick? Drop it in the comments or join the conversation on X to connect with fellow welders!