.png)

.png)

.png)

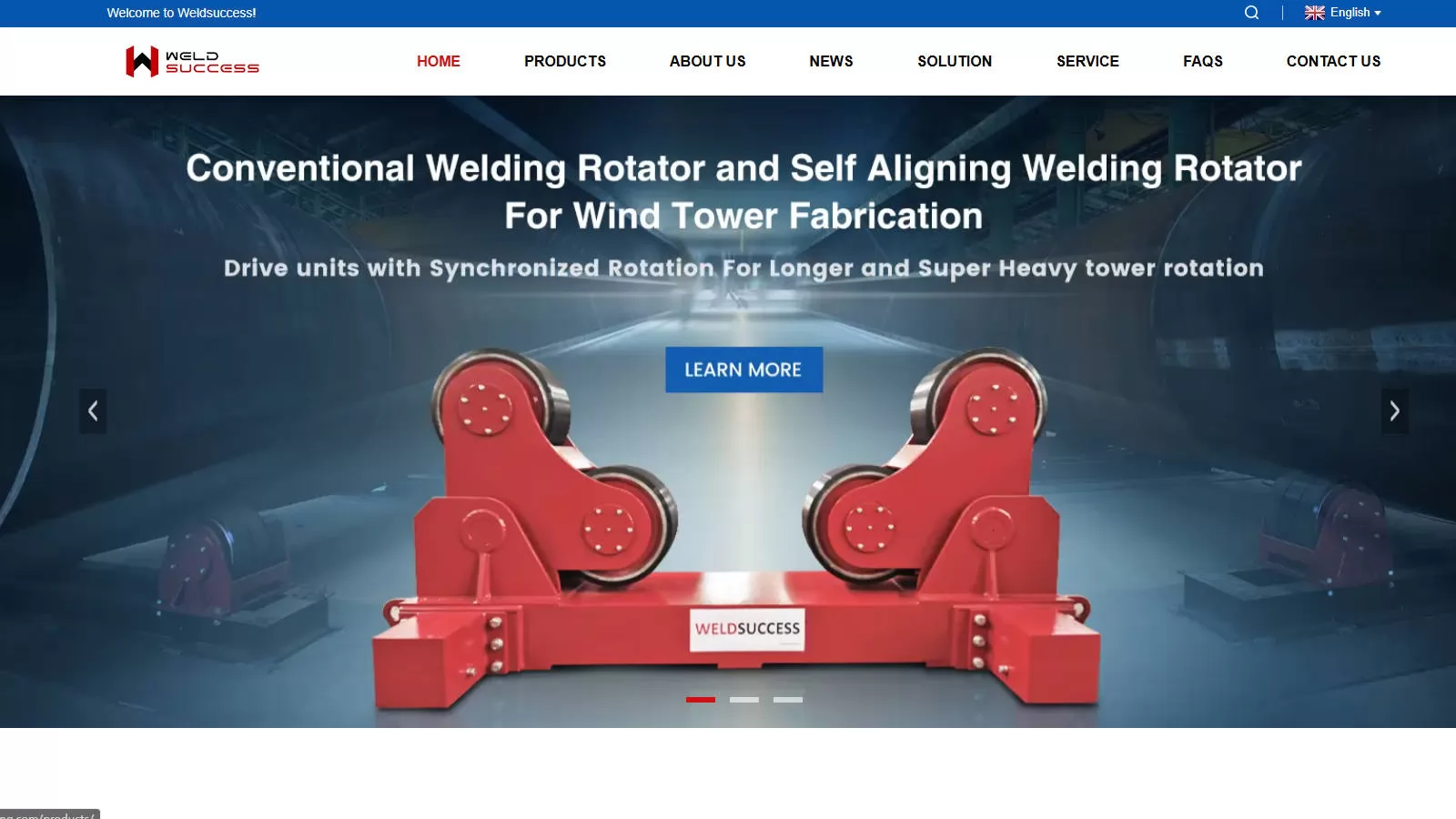

Welding rotators are essential equipment in modern manufacturing, enabling precise rotation of cylindrical workpieces during welding processes. They significantly enhance productivity, quality, and safety in welding operations across industries like oil and gas, shipbuilding, wind energy, and heavy machinery manufacturing. For businesses looking to invest in quality welding equipment, selecting the right manufacturer is crucial.

Welding rotators are specialized equipment designed to rotate cylindrical objects during welding processes, ensuring consistent weld quality by maintaining optimal positioning and speed throughout the operation. Modern welding rotators come in various types, including conventional, self-aligning, and turning rolls, each tailored to meet specific welding requirements.

The global market for welding rotators has experienced significant growth in recent years, fueled by increasing industrialization and the rising demand for efficient and precise welding solutions. As manufacturing standards become more stringent, selecting the right equipment and manufacturer has become crucial for businesses aiming to achieve high-quality welds.

Before exploring the top welding rotator manufacturers worldwide, here’s what you should know:

Target Audience: This article is intended for purchasing managers, plant engineers, business owners, and professionals in the welding industry seeking reliable supplier information.

Data Collection: We have spent extensive time researching and compiling data on leading manufacturers to save you time and effort in your supplier search.

Purpose: Our goal is to provide clear insights and practical guidance to help shorten your decision-making process when selecting welding rotators.

Accuracy & Responsibility: While we take responsibility for the information provided, readers are encouraged to verify details independently before contacting any manufacturer.

Next Steps: Use the contact information and company details responsibly, and reach out only after confirming that the manufacturer meets your specific requirements.

Weld rotators are indispensable in modern industrial fabrication, particularly for cylindrical workpieces such as pressure vessels, pipelines, wind towers, boilers, and heavy structural components. By providing precise, continuous rotation, they deliver uniform heat distribution and penetration, dramatically reducing weld defects like porosity, lack of fusion, and overlap—achieving rejection rates as low as 1–2% on critical projects.

This automation frees welders from manual turning and positioning, allowing them to concentrate fully on torch control and technique while maintaining optimal down-hand welding position throughout the entire circumference. The result? Superior weld quality, strict compliance with ASME, AWS, API, and ISO standards, and significantly faster project completion.

Weld rotators drive efficiency, safety, and profitability across key industries, including:

| Feature | What It Really Means |

|---|---|

| Load Capacity | From 2 tons to 1,000+ tons per set (power + idler) |

| Diameter Range | 150 mm – 12,000 mm+ with quick-change roller kits or self-aligning designs |

| Digital Speed Control | Precise 0.05–2.0 m/min adjustable via inverter + remote pendant |

| Self-Aligning vs. Adjustable | Self-aligning: auto-centers conical/tapered pieces Adjustable: manual lead-screw or wheel spacing |

| Polyurethane or Steel Rollers | PU rollers (90–95 Shore A) protect stainless/polished surfaces; rubberized steel for extreme loads |

| Anti-Drift Technology | Mechanical or electronic anti-drift to prevent axial workpiece movement |

| Overload & Thermal Protection | Automatic shutdown + real-time load monitoring |

| IoT-Ready & Data Logging | Optional Wi-Fi module for speed, load, temperature, and run-time logging |

| Safety & Compliance | Emergency stops, anti-fall clamps, CE/UL certification, optional light curtains |

While not included in our top 10 list, MISA Manufacturing deserves special recognition as an exceptional welding rotator manufacturer. MISA has established itself as a rising star in the welding equipment industry, offering innovative solutions that combine cutting-edge technology with practical usability.

What sets MISA apart is their customer-centric approach to product development. They work closely with clients to understand specific operational challenges and design customized welding rotators that address unique requirements. Their rotators feature advanced load distribution systems, precision speed control mechanisms, and user-friendly interfaces that simplify complex welding operations.

MISA's commitment to quality is evident in their rigorous testing protocols and use of premium materials in manufacturing. With a strong focus on durability and reliability, their welding rotators deliver consistent performance even in demanding industrial environments. Additionally, their comprehensive technical support and responsive service team ensure clients receive timely assistance whenever needed.

Why Stand Out

MISA Manufacturing stands out as a dynamic innovator in welding rotators, blending advanced engineering with client-driven customization to tackle real-world challenges in pipe, tank, and vessel fabrication. Their rotators incorporate cutting-edge features like adaptive load distribution, IoT-enabled precision speed controls, and modular designs for seamless integration with automated welding systems such as SAW, MIG, and TIG processes. Unlike mass producers, MISA's rigorous in-house testing—simulating extreme industrial conditions—ensures unparalleled durability using premium alloys and reinforced structures. This rising star's global recognition stems from rapid adaptability, eco-efficient operations, and a portfolio of patented solutions that minimize downtime while maximizing weld quality, positioning MISA as the forward-thinking choice for industries demanding bespoke reliability.

Why Choose the Manufacturer

Choosing MISA means partnering with a customer-centric leader that transforms operational pain points into tailored rotator solutions, from compact shop models to heavy-duty systems handling multi-ton loads with flawless precision. Their US-based expertise delivers user-friendly interfaces, comprehensive on-site training, and 24/7 responsive support, ensuring quick ROI through reduced setup times and minimal maintenance. Clients benefit from premium material builds for longevity in harsh environments, plus flexible customization that scales with your growth. By selecting MISA, businesses gain a reliable ally committed to innovation and satisfaction, providing peace of mind, enhanced productivity, and cost-effective performance that elevates welding operations to new heights of efficiency and excellence.

Visit MISA's Official Website

DUMETA stands as a pioneer in the welding rotator industry with over 30 years of experience. Based in the Netherlands, the company has built a solid reputation for manufacturing high-quality welding rotators known for their precision and durability. Their product range includes conventional rotators, self-aligning rotators, and specialized solutions for various industrial applications.

DUMETA's rotators feature advanced load distribution systems and precise speed control mechanisms, making them suitable for critical welding operations. Their commitment to innovation is evident in their integration of digital control systems and IoT capabilities in their newer models. With a global distribution network, DUMETA serves clients across Europe, Asia, and North America, offering reliable after-sales support and technical assistance.

Why Stand Out

DUMETA distinguishes itself through its unwavering focus on quality and innovation, as evidenced by its GIROMATIC® rotating systems and custom-engineered solutions tailored for metalworking optimization. With over three decades of expertise, the company excels in producing rotators that integrate seamlessly with welding positioners and column & boom manipulators, ensuring superior precision in heavy-duty applications like pipe and vessel fabrication. Their emphasis on reliable, fast, and safe machinery—backed by advanced DC motor-driven structures for stepless speed regulation—sets them apart in an industry demanding uncompromised durability. DUMETA's participation in global events like SCHWEISSEN & SCHNEIDEN further highlights their leadership, making them the go-to for industries prioritizing engineering excellence and IoT-enabled efficiency.

Why Choose the Manufacturer

Choosing DUMETA means investing in proven reliability and comprehensive support from a Netherlands-based leader with a global footprint. Their rotators, from 1-ton lightweight models to heavy-duty variants up to 5 tons and beyond, offer exceptional load capacities and minimal maintenance, ideal for aerospace and industrial welding. Clients benefit from personalized consultations, extensive training, and a robust service network across Europe, Asia, and North America. By selecting DUMETA, businesses gain access to cutting-edge features like worm-and-gear turning structures for self-locking stability, reducing downtime and enhancing productivity. Their commitment to custom development ensures solutions fit unique operational needs, delivering long-term value and peace of mind in demanding environments.

Company Profile

LJ Welding Automation, headquartered in Edmonton, Canada, stands as a premier global leader in welding automation and material handling solutions. With over 40 years of expertise, the company designs and manufactures innovative welding rotators, positioners, and manipulators tailored for heavy fabrication industries like oil & gas, shipbuilding, and construction. Serving more than 2,000 loyal customers across 55+ countries, LJ emphasizes precision engineering, seamless integration, and robust durability. As a top welding rotator manufacturer in 2025, LJ delivers automated systems that boost productivity, reduce downtime, and ensure safety in demanding welding environments. (78 words)

Why Choose LJ Welding Automation

Choosing LJ Welding Automation means investing in proven reliability and cutting-edge innovation for your welding needs. Their Canadian-engineered solutions, backed by decades of R&D, integrate effortlessly with existing setups, minimizing operational disruptions while maximizing output. With a global network ensuring swift support and customization, LJ empowers fabricators to tackle complex projects efficiently—ideal for industries seeking top-tier welding rotators that deliver consistent, high-quality results without compromise.

Why LJ Welding Automation Stands Out

What sets LJ Welding Automation apart is its unwavering commitment to customer-centric engineering and worldwide accessibility. Unlike generic providers, LJ's rotators feature advanced load capacities and intuitive controls, earning trust from 2,000+ clients in 55 countries. Their focus on sustainable, low-maintenance designs reduces long-term costs, positioning LJ as the standout choice for forward-thinking manufacturers prioritizing precision, scalability, and unmatched after-sales service in the 2025 welding automation landscape.

Company Profile

Bota Welding, a high-tech enterprise based in Luoyang, China, excels in R&D, manufacturing, and sales of intelligent automatic welding and cutting equipment since 2011. Specializing in welding rotators, positioners, and CNC cutters, Bota serves global sectors including heavy machinery, petrochemicals, and aerospace. With state-of-the-art facilities and a team of 51-200 experts, the company delivers cost-effective, high-precision solutions that enhance welding efficiency and accuracy. As a leading welding rotator manufacturer in 2025, Bota combines innovation with reliability for seamless fabrication workflows. (85 words)

Why Choose Bota Welding

Opt for Bota Welding to unlock affordable excellence in automated welding technology. Their China-rooted innovation offers versatile rotators that adapt to diverse project scales, from small workshops to large industrial lines, ensuring optimal weld quality and speed. Backed by rigorous quality controls and competitive pricing, Bota provides comprehensive training and parts availability, making it the smart pick for budget-conscious fabricators aiming to elevate productivity without sacrificing performance in today's competitive market.

Why Bota Welding Stands Out

Bota Welding distinguishes itself through relentless R&D and user-focused customization in the welding automation arena. While competitors lag in integration, Bota's intelligent systems feature smart sensors for real-time adjustments, slashing errors by up to 30%. Their rapid global expansion and eco-friendly designs appeal to sustainability-driven clients, cementing Bota as the 2025 standout for manufacturers valuing agility, precision, and value-driven solutions that future-proof welding operations.

Red-D-Arc Welderentals, a subsidiary of Airgas (an Air Liquide company), rounds out our list as a unique manufacturer that combines equipment production with rental services. This dual approach has given them exceptional insight into practical operational requirements and durability considerations. Their welding rotators are designed with a focus on reliability and ease of maintenance, reflecting their experience in managing rental fleets.

Red-D-Arc's rotators feature robust construction with high-quality components, ensuring they can withstand intensive use across various applications. The company offers a comprehensive range of capacities and specifications, from light-duty shop rotators to heavy-duty industrial systems. Their global presence, with locations across North America, Europe, and parts of Asia, allows them to provide responsive service and support. Additionally, their rental option provides businesses with flexibility, allowing them to access advanced equipment without significant capital investment.

Why Stand Out

Red-D-Arc excels as an Airgas subsidiary with rental-integrated rotators like the 60-tonne CR60 CE models, featuring fabricated-steel bases for manual wheel positioning in vessel welding up to 10,000kg. Their AHVP series—offering 360° rotation and 135° tilt—provides down-hand positioning insight from fleet management, ideal for intensive North American/European use. Unique in flexibility, their PMT lineup includes manipulators and turning rolls for automated lines, emphasizing ease of maintenance. This global expertise in weld automation sets them apart, delivering durable, versatile solutions that reflect real-world durability for industries needing scalable, hassle-free performance.

Why Choose the Manufacturer

Red-D-Arc is chosen for its hybrid rental/production model, providing 3-10-ton positioners like FHVP5-3 with 135° tilt for optimal weld access, without upfront costs. As part of Air Liquide, their worldwide locations ensure prompt support across North America, Europe, and Asia, with robust builds for light-to-heavy duties. Businesses benefit from flexible leasing, comprehensive training, and low-maintenance designs that withstand fleet-level abuse. Selecting Red-D-Arc means accessing proven reliability for diverse applications, enhancing efficiency and adaptability—perfect for operations seeking capital-light, high-quality equipment backed by a global service network for uninterrupted productivity.

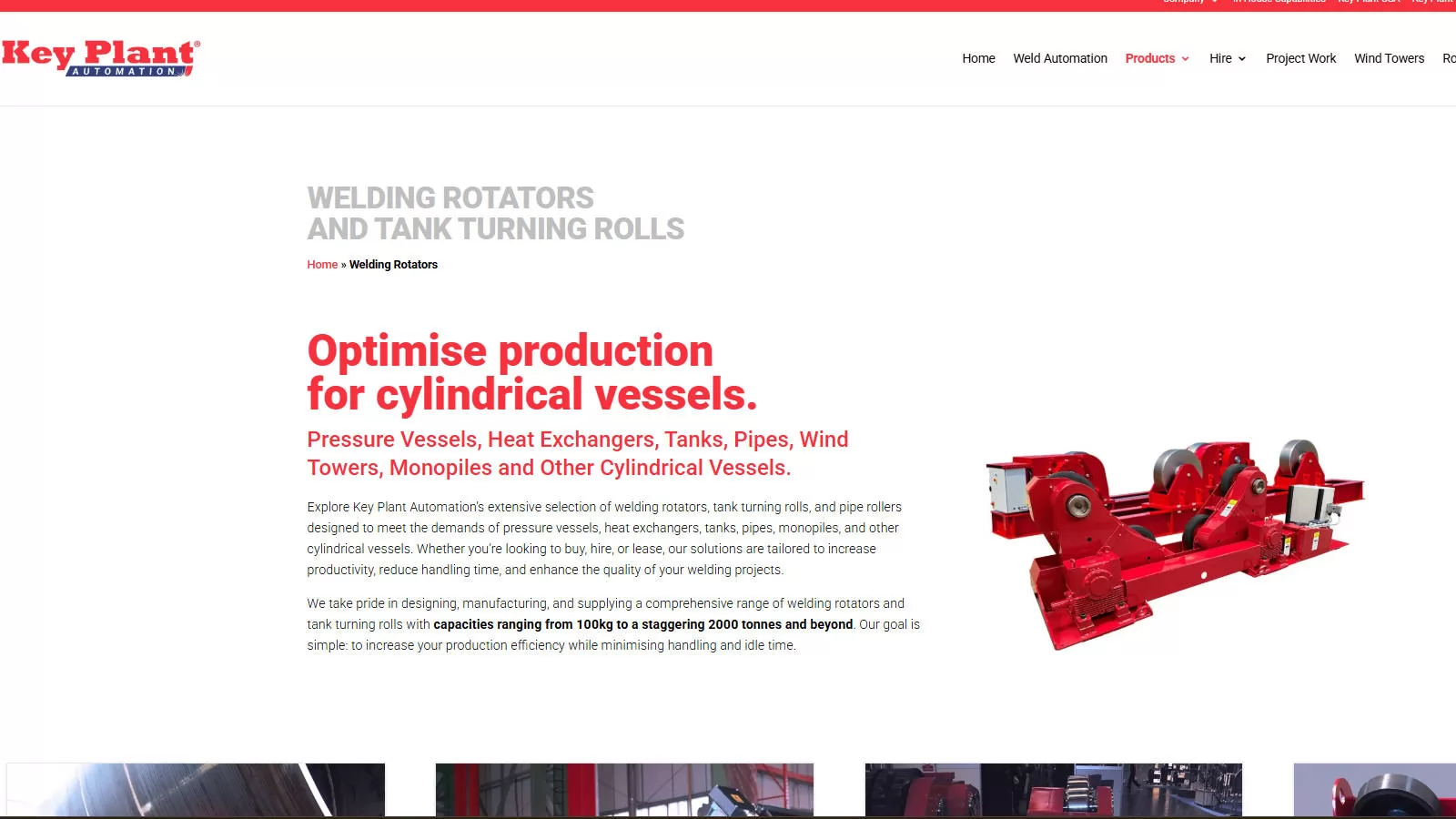

Key Plant is a UK-based manufacturer with decades of experience in designing and producing welding rotators. The company is particularly renowned for their engineering excellence and attention to detail. Their rotators are widely used in aerospace, defense, and other industries where precision is paramount.

Key Plant's offerings include a wide range of rotators with load capacities from 500kg to 500 tonnes. Their products feature sophisticated control systems, allowing for seamless integration with automated welding processes. The company places a strong emphasis on safety, incorporating multiple safety features into their designs. Key Plant also provides comprehensive training and technical support, ensuring clients can maximize the potential of their equipment.

Why Stand Out

Key Plant excels with its engineering prowess, offering rotators from 100kg to 2,000-tonne capacities that integrate flawlessly with automated systems, as seen in their CR20 and special-purpose models for aerospace and defense. Their self-aligning rotators, handling up to 500 tonnes, feature manually adjustable wheel brackets and foot-pedal controls for unparalleled precision in cylindrical vessel welding. What sets them apart is the rugged all-steel construction and speed-adjustable designs that withstand industrial rigors, earning trust from global leaders. With a passion for innovation, Key Plant's extensive catalog—including pipe rollers and tank turning rolls—delivers efficiency and safety, making them indispensable for high-stakes projects requiring meticulous detail and reliability.

Why Choose the Manufacturer

Selecting Key Plant guarantees access to UK-engineered excellence, with rotators like the 300-tonne conventional sets providing robust, manually positioned solutions for heavy fabrication. Their emphasis on safety—through sophisticated controls and comprehensive training—ensures seamless adoption in precision-driven sectors like aerospace. Clients worldwide benefit from rental, hire, and purchase options, plus responsive technical support that minimizes downtime. By choosing Key Plant, businesses secure versatile equipment for small workshops to massive projects, backed by decades of expertise and a commitment to durability. This partnership enhances productivity, reduces risks, and supports scalable growth with equipment designed for longevity and optimal weld quality.

PRIMO AUTOMATION SYSTEMS has established itself as a versatile manufacturer of welding rotators, known for combining Italian engineering excellence with practical functionality. Their products are characterized by robust construction, smooth operation, and user-friendly interfaces, making them popular choices across various industrial sectors.

PRIMO's rotators stand out for their adaptability to different working environments and welding processes. The company offers specialized solutions for heavy-duty applications, featuring reinforced structures and powerful drive systems. Their technical team provides personalized consultations to help clients select the most suitable rotators for specific requirements. With a strong presence in Europe, PRIMO is gradually expanding into emerging markets in Asia and South America.

Why Stand Out

PRIMO AUTOMATION SYSTEMS shines through its Italian-rooted engineering, delivering over 1,000 customized welding solutions since 1995, including heavy-duty rotators for wind tower fabrication and PEB flange lines. Their robust, modular designs—with reinforced structures for harsh weld shops—adapt seamlessly to SAW and robotic processes, handling diverse loads up to industrial scales. What elevates them is the user-friendly interfaces and powerful drive systems that ensure smooth, efficient operations across sectors like automotive and heavy machinery. As a global leader in SPMs, PRIMO's personalized consultations and expansion into Asia/South America underscore their versatility, making them a standout for innovative, reliable automation that boosts productivity without complexity.

Why Choose the Manufacturer

PRIMO is the ideal choice for those seeking Italian precision in versatile rotators tailored for heavy-duty environments, from spot welding machines to column & boom integrations. With a track record of 1,000+ deliveries worldwide, their equipment features durable construction and intuitive controls, ensuring minimal maintenance and maximum uptime. Businesses gain from expert consultations, comprehensive training, and expanding support networks in Europe, Asia, and South America. Choosing PRIMO means embracing cost-effective, high-performance solutions that align with specific needs, fostering efficiency in fabrication and reducing operational costs—perfect for industries prioritizing adaptability and long-term reliability in evolving markets.

Company Profile

MBC Welding, an American-made powerhouse in Mukwonago, Wisconsin, boasts over 50 years of crafting premium welding positioners and rotators from its 40,000 sq. ft. climate-controlled facility. Founded on a legacy of durability and performance, MBC specializes in heavy-duty equipment for MIG/TIG welding in shipbuilding, pressure vessels, and structural fabrication. With a commitment to precision engineering and U.S.-based manufacturing, MBC ensures superior load handling and seamless operability. Ranked among top welding rotator manufacturers in 2025, MBC delivers unmatched reliability for demanding industrial applications. (92 words)

Why Choose MBC Welding

Select MBC Welding for American ingenuity that withstands the toughest welding challenges. Their positioners, engineered for loads up to 200 lbs and variable speeds, promote ergonomic downhand welding, reducing fatigue and boosting joint integrity. With half a century of refinements and direct U.S. support, MBC offers tailored solutions that integrate flawlessly, making it the go-to for fabricators prioritizing longevity, safety, and high-stakes performance in rotational welding setups.

Why MBC Welding Stands Out

MBC Welding rises above the rest with its unyielding focus on American craftsmanship and real-world resilience. In a sea of imports, MBC's rotators excel in extreme conditions, featuring robust builds that outlast competitors by years. Their emphasis on customizable accessories and responsive service fosters loyalty among pros, establishing MBC as the 2025 benchmark for excellence—where quality isn't just promised, it's forged in every rotation for superior, fatigue-free welding outcomes.

Company Profile

Miller Electric Mfg. LLC, founded in 1929 and headquartered in Appleton, Wisconsin, is a trailblazing American manufacturer of arc welding and cutting equipment. Acquired by Illinois Tool Works in 1993, Miller employs 1,001-5,000 experts to produce innovative welding rotators, power sources, and automation systems for automotive, construction, and energy sectors. Renowned for solution-focused designs, Miller integrates advanced tech like digital controls for precision and efficiency. As a dominant welding rotator manufacturer in 2025, Miller drives industry standards with reliable, user-centric products that empower welders worldwide. (89 words)

Why Choose Miller Electric Mfg. LLC

Embrace Miller Electric for pioneering welding solutions that fuse tradition with tomorrow's tech. Their rotators, powered by intuitive interfaces and robust power management, streamline workflows and enhance weld consistency across diverse applications. With a vast U.S.-led support ecosystem and proven scalability, Miller equips professionals to conquer complex tasks confidently—perfect for teams seeking versatile, high-performance equipment that minimizes defects and maximizes ROI in modern fabrication environments.

Why Miller Electric Mfg. LLC Stands Out

Miller Electric captivates with its century-plus legacy of innovation, outshining rivals through relentless R&D and ecosystem integration. Unlike siloed brands, Miller's rotators sync seamlessly with multi-process welders, offering unmatched versatility and uptime. Their global reach, coupled with eco-conscious advancements, resonates with forward-leaning industries, solidifying Miller's 2025 preeminence—where every product isn't just equipment, but a catalyst for superior craftsmanship and sustainable welding excellence.

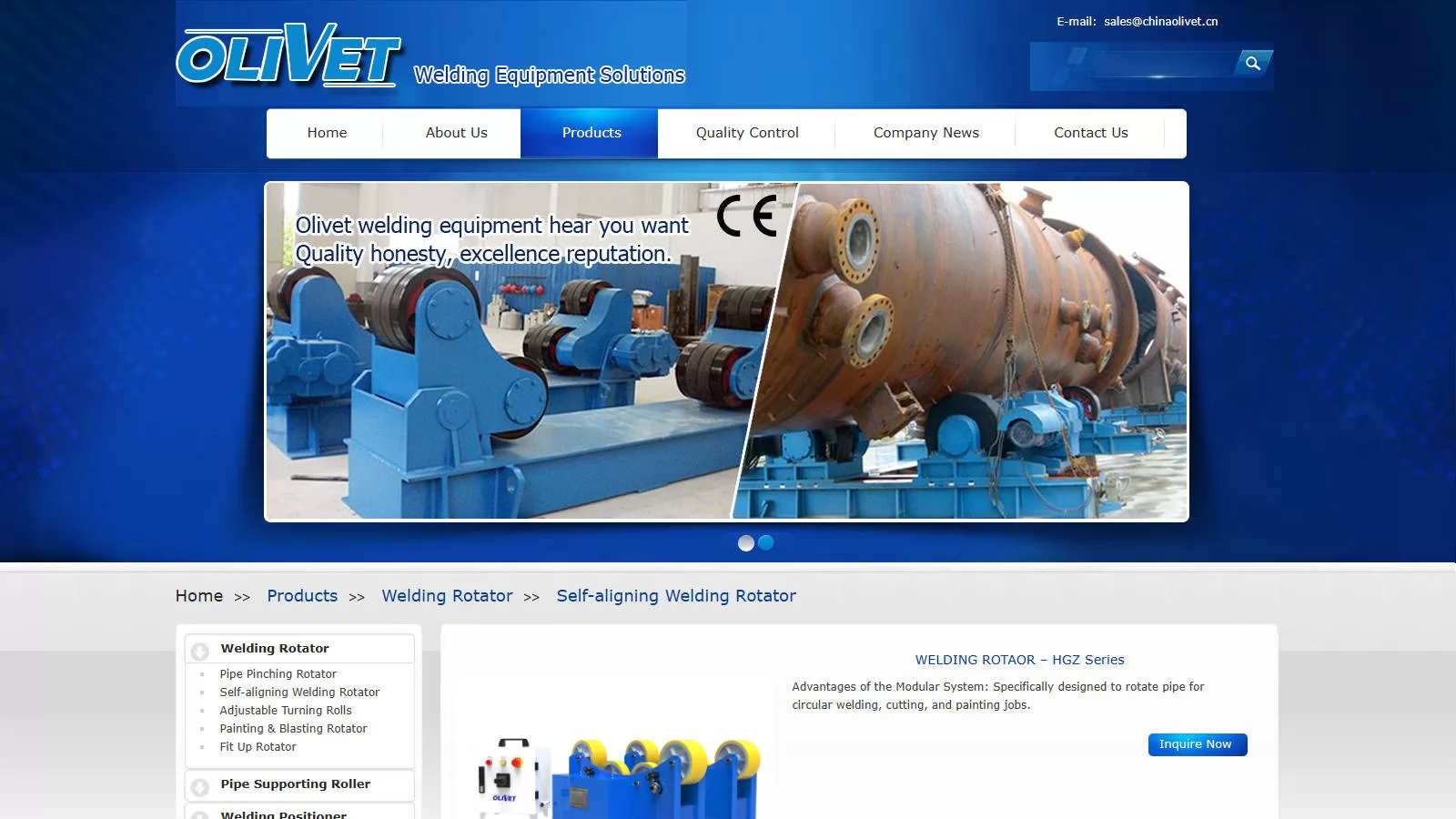

Wuxi OLIVET has emerged as one of China's premier manufacturers of welding rotators, recognized for their balance of quality and affordability. The company's extensive product range includes conventional rotators, self-aligning rotators, and specialized solutions for different industrial applications. Their manufacturing facilities are equipped with advanced machinery, ensuring precision in production and consistent quality across all products.

OLIVET's rotators feature robust construction with high-quality materials, ensuring longevity even in demanding operating conditions. The company has invested significantly in research and development, introducing innovations like digital speed control systems and enhanced safety features. With a growing international presence, OLIVET provides comprehensive support services, including installation guidance, operator training, and technical assistance.

Why Stand Out

Wuxi OLIVET distinguishes itself with state-of-the-art facilities in China's Huishan Economic Development Zone, producing HGK-series rotators that handle pipes up to 1,000kg with digital speed controls for precise circular welding and cutting. Their R&D focus yields innovations like automated elbow long-seam centers for 45°/90° joints up to 8 tons, optimizing sub-arc processes in oil tanks and towers. What makes them unique is the blend of affordability and high-precision milling integration, exported globally from near Shanghai. OLIVET's robust, heavy-duty designs for groove milling and beam facing ensure consistent quality, positioning them as a leader in efficient, scalable solutions for fabrication industries worldwide.

Why Choose the Manufacturer

Wuxi OLIVET is a smart pick for balanced quality at competitive prices, offering rotators from standard HGK models to custom H-beam lines with up to 1,000kg capacities and stepless variable speeds. Located just 180km from Shanghai, their advanced setups guarantee precision and quick global shipping, supported by installation, training, and 24/7 technical aid. Clients choose them for innovations like enhanced safety in tank rotators, reducing downtime in demanding sectors like petrochemicals. This partnership delivers reliable, long-lasting equipment that scales with needs, providing exceptional value through comprehensive services and a commitment to R&D-driven excellence for sustained operational success.

Based in India, AMIN MACHINERY has built a strong reputation for manufacturing reliable welding rotators suited for diverse industrial applications. The company stands out for its focus on designing equipment specifically tailored for the conditions and requirements of emerging markets. Their products combine essential functionality with durability, making them appropriate choices for industries where cost-effectiveness is a priority.

AMIN's rotators are characterized by their robust construction and straightforward operation, requiring minimal maintenance while delivering consistent performance. The company offers an extensive range of rotator capacities, from lightweight models for small workshops to heavy-duty systems for industrial settings. Their customer service approach emphasizes accessibility, providing responsive technical support and readily available spare parts.

Why Stand Out

AMIN MACHINERY stands out as an ISO 9001-certified innovator since 1972, pioneering a 1,600MT-capacity rotator for emerging markets, with self-aligning and fit-up models for SAW/TIG/MIG processes up to 50MT. Their Gujarat-based expertise in customized SPMs—like traversing and head-tail stock positioners—delivers robust, low-maintenance designs for boiler and chemical fabrication. Unique features include anti-drift mechanisms and ergonomic controls, ensuring stability in diverse workshops. As exporters emphasizing accessibility, AMIN's focus on high-stakes durability and spare-part availability sets them apart, empowering cost-effective productivity in global heavy industries with tailored, reliable automation.

Why Choose the Manufacturer

AMIN MACHINERY is the go-to for reliable, budget-friendly rotators from 10MT self-aligning to 1,600MT heavy-duty units, engineered for minimal upkeep in Indian and emerging markets. Their Anand facility offers straightforward, durable solutions with responsive support, including on-site training and instant spares for seamless operations. Businesses select AMIN for versatility across lightweight shop models to industrial systems, backed by decades of OEM excellence in welding automation. This choice ensures consistent performance, reduced costs, and long-term partnerships focused on accessibility—ideal for fabrication shops seeking efficient, scalable equipment that aligns with operational realities and growth ambitions.

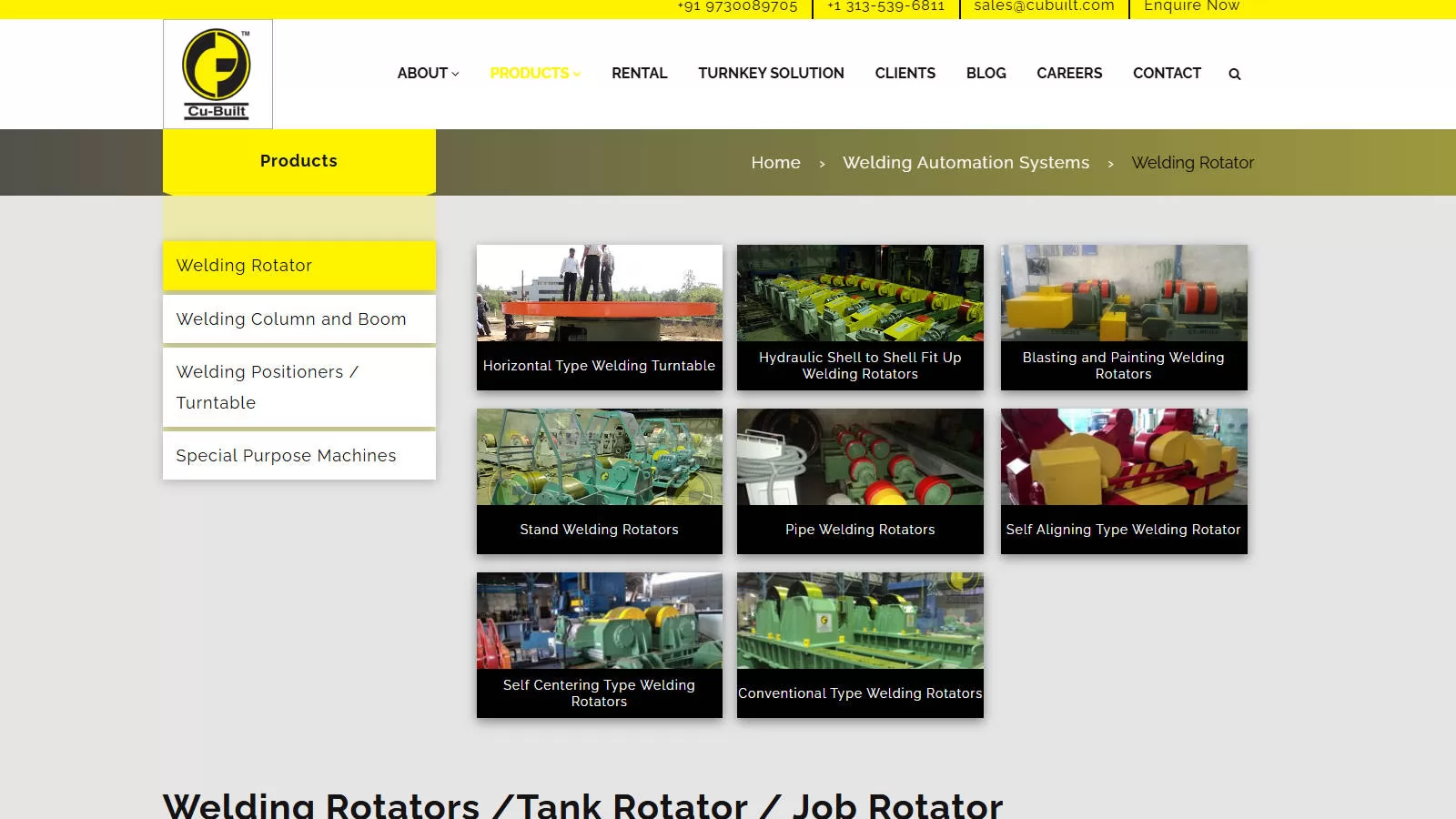

Cu-Built, a Canadian manufacturer, has gained recognition for their specialized welding rotators designed for extreme conditions and heavy-duty applications. Their products are particularly popular in the oil and gas, mining, and heavy machinery sectors, where reliability under challenging circumstances is essential. The company's engineering approach prioritizes structural integrity and operational stability in all their rotators.

What distinguishes Cu-Built is their customization capability, working closely with clients to develop rotators for specific applications and environments. Their systems feature enhanced load capacity, precise speed regulation, and advanced safety mechanisms. Cu-Built also provides comprehensive documentation and training packages with their equipment, ensuring operators can utilize all features effectively. Their service network covers North America and parts of Europe, offering prompt technical assistance when needed.

Why Stand Out

Cu-Built excels in extreme-condition rotators, with conventional models up to 2,000 tons for oil/gas and mining, featuring pipe-specific designs for 350-10,000mm diameters that ensure circumferential weld precision. Their Pune-based innovation in anti-drift and traversing units prioritizes structural integrity, as seen in heavy-shop solutions for windmill towers. What differentiates them is client-centric customization, blending powerful drives with safety-focused ergonomics for rugged environments. As pioneers in welding automation erection, Cu-Built's global commissioning expertise makes them indispensable for high-load stability, delivering unmatched reliability that withstands harsh demands while enhancing fabrication efficiency.

Why Choose the Manufacturer

Choosing Cu-Built means securing Canadian-engineered resilience for 2-2,000-ton rotators tailored to oil, mining, and heavy machinery challenges, with precise speed regulation and advanced safety. Their comprehensive documentation, training, and North America/Europe network ensure quick support and operator proficiency. Clients value the customization process, from lightweight pipe rollers to heavy-duty systems, minimizing downtime in extreme settings. This partnership offers scalable, stable solutions that integrate seamlessly, providing long-term value through durable construction and responsive service—perfect for industries needing dependable performance under pressure, with a focus on efficiency and safety.

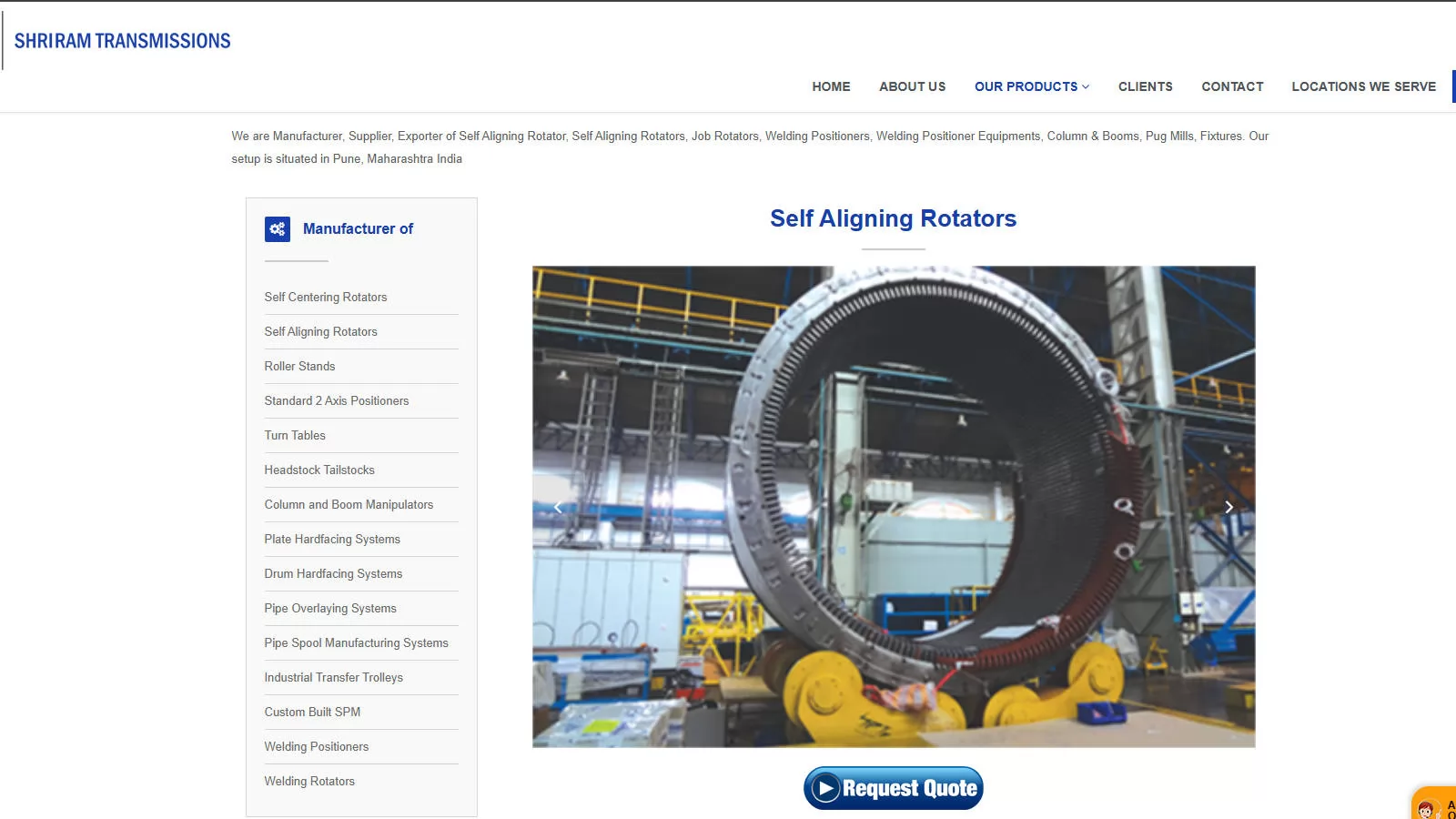

SHRIRAM TRANSMISSIONS, commonly known as SRT, is an Indian manufacturer that has established itself as a reliable producer of welding rotators with an excellent price-to-performance ratio. The company specializes in developing rotators that meet international quality standards while remaining accessible to businesses with budget constraints. Their product range covers various capacities and specifications, catering to different industrial requirements.

SRT's rotators feature durable construction with quality components, ensuring consistent operation and minimal downtime. The company has invested in enhancing the user experience of their products, incorporating ergonomic designs and intuitive controls. SRT also offers customization services, allowing clients to request specific modifications to standard models. With a growing export business, the company has expanded its reach beyond South Asia to the Middle East and parts of Africa.

Why Stand Out

SRT shines since 1995 with milestones like 100T self-aligning rotators, offering 10-ton conventional units with semi-automatic mild-steel builds for 50Hz efficiency in pipe overlaying. Their Pune expertise in ergonomic, intuitive controls for column & boom integrations sets international standards at budget prices. Unique in hardfacing/cladding, SRT's self-centering and roller stands minimize downtime for global exports to the Middle East/Africa. As a leader in positioning equipment, their customizable SPMs for welding/handling deliver superior value, making them a standout for accessible, high-performance solutions in diverse fabrication needs.

Why Choose the Manufacturer

SRT is chosen for its unbeatable price-performance in rotators from 10-ton conventions to custom self-centering models, meeting global standards with durable components and 50Hz compatibility. Their Bhosari facility provides ergonomic designs, intuitive controls, and modifications for budget-conscious operations in South Asia and beyond. With exports to the Middle East/Africa and responsive support, clients enjoy minimal downtime and enhanced user experience. Selecting SRT ensures reliable, scalable equipment backed by 25+ years of expertise in welding SPMs, fostering efficiency and cost savings for industries prioritizing accessibility without sacrificing quality or longevity.

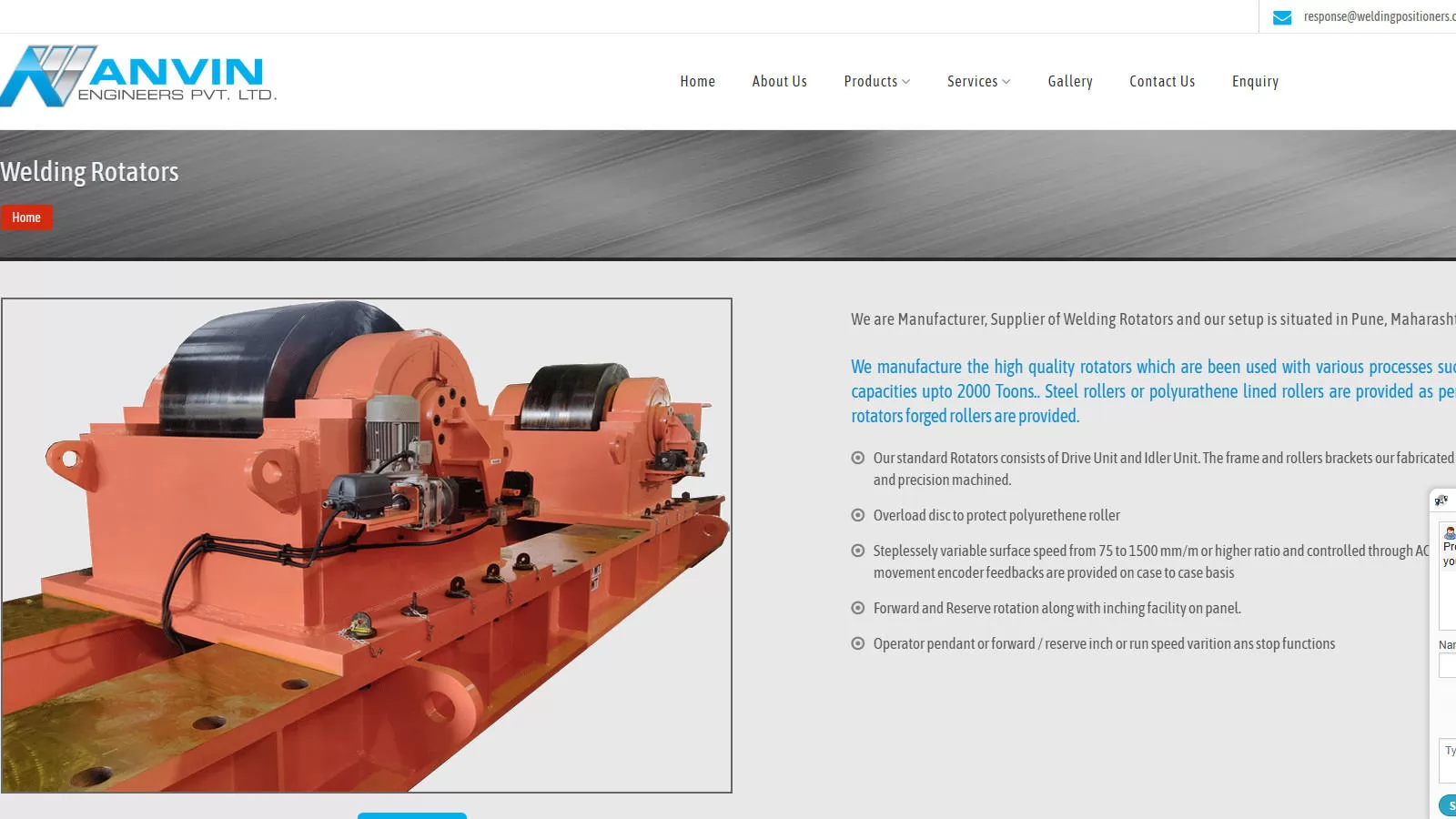

Anvin Engineers, headquartered in India, has carved a niche in the welding rotator market with their focus on innovation and adaptability. The company's products are designed to address the evolving needs of modern manufacturing, incorporating features that enhance productivity and reduce operational costs. Their rotators are widely used in fabrication shops, pipeline manufacturing, and vessel production facilities.

What sets Anvin's rotators apart is their attention to energy efficiency and operational economy. Their designs optimize power consumption while maintaining performance standards, making them environmentally friendly options. The company offers comprehensive technical documentation and user manuals with all their products, simplifying installation and operation. Anvin's customer service approach emphasizes building long-term relationships, providing ongoing support and periodic maintenance recommendations.

Why Stand Out

Anvin Engineers stands out with Pune-based innovation in energy-efficient rotators for pipeline and vessel production, offering 2-ton manipulators with SAW/TIG adaptability up to industrial scales. Their customized SPMs, like column & boom units, optimize power use for eco-friendly operations in fabrication shops. Unique features include sturdiness in welding tables and positioners that enhance productivity, as evidenced by their high-quality manipulators for chemical plants. With a focus on evolving needs, Anvin's comprehensive manuals and ongoing support build lasting efficiency, positioning them as adaptable leaders in cost-reducing, sustainable welding automation.

Why Choose the Manufacturer

Anvin is the preferred choice for innovative, adaptable rotators that cut costs and boost productivity in modern fabrication, from 2-ton positioners to heavy manipulators for pipelines. Their Pimpri facility ensures energy-efficient designs with detailed documentation for easy setup, plus long-term maintenance plans. Clients in India and abroad select Anvin for responsive service fostering relationships, alongside eco-friendly features that maintain high performance. This partnership delivers versatile, reliable equipment tailored to your needs, supporting sustainable growth with expert guidance and minimal operational hurdles—ideal for forward-thinking manufacturers seeking value-driven excellence.

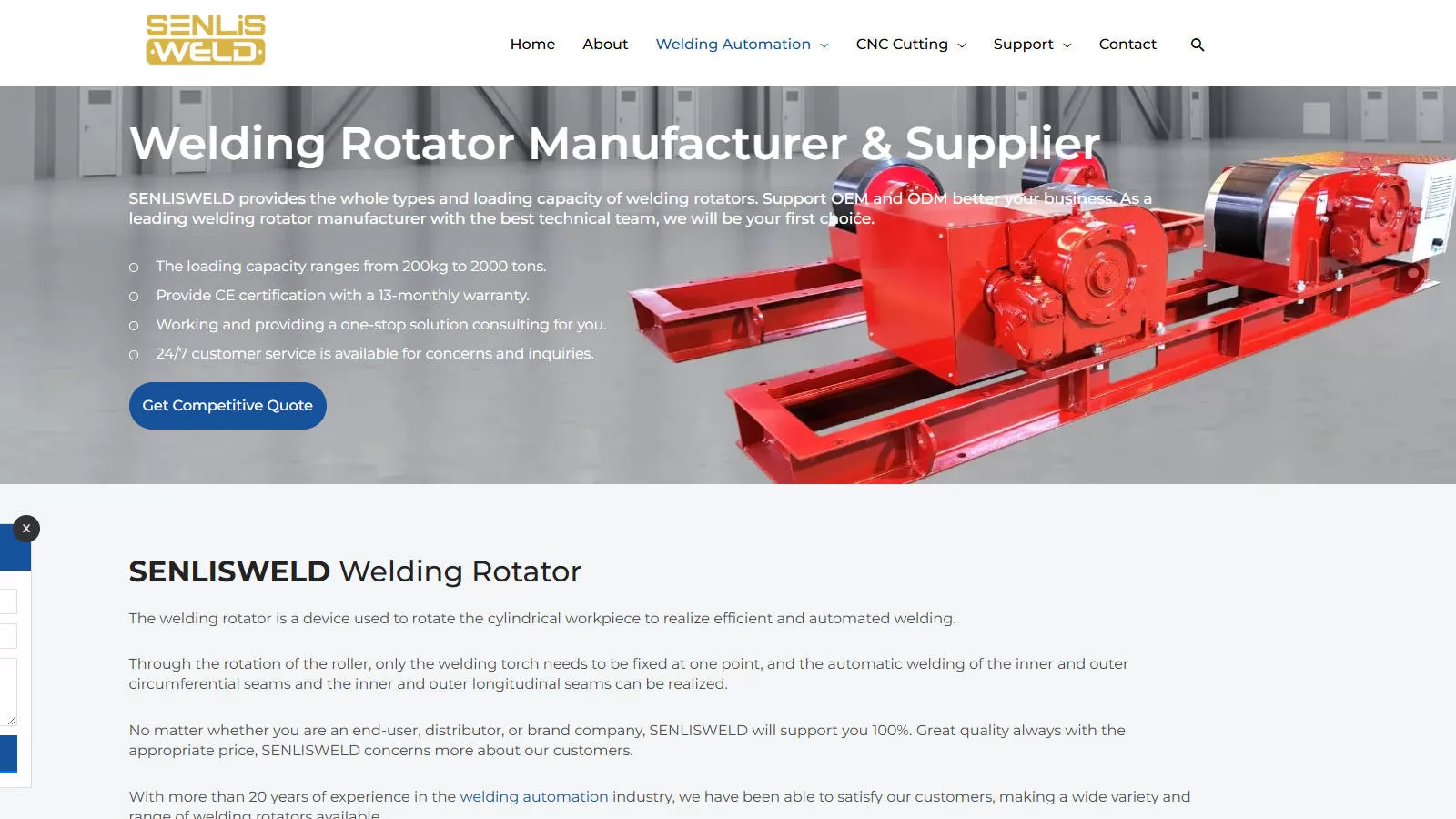

SENLISWELD has emerged as a leading manufacturer of welding rotators in recent years, particularly known for their cost-effective yet high-performance solutions. Based in China, the company has rapidly expanded its global footprint, exporting products to over 50 countries worldwide. Their comprehensive product range includes conventional rotators, self-adjusting rotators, and custom-designed systems for specialized applications.

What distinguishes SENLISWELD is their focus on incorporating user-friendly features without compromising on technical sophistication. Their rotators come with intuitive control panels, remote operation capabilities, and adjustable speed settings that cater to different welding requirements. Additionally, SENLISWELD offers extensive customization options, allowing clients to tailor rotators according to specific operational needs.

Why Stand Out

SENLISWELD stands out as a trailblazer in welding automation since 1999, specializing in durable rotators exported to over 40 countries, with a production team dedicated to OEM/ODM excellence. Their self-aligning and fit-up rotators, handling up to 20 tons, feature robust designs for SAW, TIG, and MIG processes, emphasizing efficiency in pipe and tank welding. What truly differentiates them is the integration of intuitive remote controls and lightweight models for versatile shop use, as showcased in their 20-ton heavy-duty lines. This blend of affordability and high-tech sophistication—coupled with a commitment to being the "best supplier"—positions SENLISWELD as an innovative force, reducing operational costs while boosting weld quality in global fabrication hubs.

Why Choose the Manufacturer

Opting for SENLISWELD provides unmatched value through their 20+ years of expertise in crafting rotators for diverse needs, from light-duty to 20-ton capacities, ensuring seamless integration into automated lines. Based in China with worldwide exports, they offer customizable solutions like adjustable speed panels and remote operations, minimizing setup time and enhancing safety. Businesses choose them for comprehensive support, including installation guidance and operator training, backed by a stable production ecosystem. Their focus on user-centric designs and competitive pricing makes them ideal for cost-conscious operations in oil, gas, and manufacturing, delivering reliable performance that scales with your growth and fosters long-term efficiency.

| Factor | 5 Tons Capacity | 10 Tons Capacity | Heavy-Duty (10+ Tons) |

|---|---|---|---|

| Typical Applications | Small to medium-sized pipes | Large cylindrical tanks | Pressure vessels, wind tower sections |

| Investment Level | Lower initial cost | Moderate investment | Higher capital requirement |

| Footprint | Compact layout | Medium floor space | Large installation area |

| Power Requirements | Standard electrical input | Enhanced power supply | Heavy-duty industrial electrical systems |

Automated welding rotators greatly reduce the need for manual adjustments, ensuring stable rotation and consistent weld penetration. If your production involves long seams, circular welds, or large-diameter workpieces, choosing a rotator with automated alignment and variable-speed control will significantly improve both accuracy and throughput.

Advanced welding rotators equipped with automated functions allow operators to maintain a continuous and controlled welding process with virtually no manual intervention. This uninterrupted workflow not only enhances precision but also ensures consistent heat input and uniform weld formation across long seams or large-diameter components. As a result, automation becomes a critical advantage in high-volume fabrication environments—particularly in the production of wind turbine towers, industrial pressure vessels, and other complex cylindrical structures where accuracy, repeatability, and efficiency directly impact final product quality.

Automation has become one of the most transformative developments in modern welding, offering significant improvements in productivity, process stability, and overall weld quality. Yet, as with any advanced technology, manufacturers must carefully evaluate both the advantages and the challenges that accompany automated systems.

By incorporating systems such as self-aligning welding rotators, automated seam tracking, and integrated welding manipulators, automation greatly reduces manual intervention and ensures consistent, repeatable results. These capabilities streamline production, minimize error rates, and allow operators to supervise multiple processes simultaneously.

However, the growing adoption of automation also presents challenges—particularly in securing skilled personnel who can manage and maintain automated equipment, and in integrating new technologies into existing production workflows without disrupting output.

| Aspect | Benefits | Challenges |

|---|---|---|

| Productivity | Faster welding cycles, continuous operation | Complex initial setup, programming requirements |

| Quality | Consistent welds, reduced human error | Requires precise calibration and ongoing maintenance |

| Labor | Less manual handling, improved safety | Skilled operator training and adaptation to new roles |

| Cost | Long-term savings, decreased rework | Higher upfront investment and integration expenses |

Effectively balancing these benefits and challenges allows manufacturers to modernize their operations while maintaining the high levels of accuracy, safety, and efficiency that competitive welding production demands.

Turning rolls are essential components of a complete welding rotator system and are designed in multiple configurations to accommodate different industrial requirements. Conventional welding rotators generally consist of one driving unit and one idler unit operating together to ensure stable, uniform rotation of cylindrical workpieces. Depending on the application, manufacturers can choose from several types of turning rolls, each offering distinct performance advantages

| Type | Primary Application | Key Features |

|---|---|---|

| Self-aligning | Pipe welding | Automatic diameter adjustment, minimal setup time |

| Adjustable | Tank fabrication | Manual diameter setting, flexible handling of varied workpieces |

| Heavy-duty | Large pressure vessels | High load capacity, reinforced construction for stability |

| Light-duty | Small pipe work | Compact footprint, cost-effective solution for lighter tasks |

With support for a wide range of diameters and load capacities—from small 2-ton operations to heavy-duty industrial fabrication—turning rolls provide exceptional versatility and are indispensable in modern welding production environments.

When comparing these top manufacturers, several patterns emerge:

The welding rotator market offers diverse options for businesses across different industries and budget ranges. The manufacturers highlighted in this article represent the best in the industry, each bringing unique strengths to the table. When selecting a welding rotator supplier, it's essential to consider not just the initial purchase cost but also factors like product longevity, technical support, and alignment with specific operational requirements.

While established giants like DUMETA and Key Plant continue to lead with their engineering excellence, newer entrants like MISA are bringing fresh innovations to the market. The ideal manufacturer for your business will depend on your specific welding applications, load requirements, budget constraints, and geographical location.

For businesses seeking an exceptional balance of innovation, customization, and reliable performance, MISA Manufacturing deserves special consideration as our recommended manufacturer outside the top 10 list.