How We Evaluated the Top Welding Manipulators Manufacturers (2026 Methodology)

- Product range and technical capability

- Customization and engineering support

- Project references and industry experience

- Global service & spare parts supply

- Certifications, warranty and after-sales

- Price / lead time / total cost of ownership

Professional Comparison Table — Top 10 Welding Manipulators Manufacturers (Plus Recommended MISA)

| Manufacturer | Core Application Focus | Automation Level | Customization Capability | Industry Fit | Global Support | Price Positioning | Best For |

|---|---|---|---|---|---|---|---|

| Lincoln Electric | Integrated welding automation, SAW/MIG/robotic lines | High — full mechanized & robotic-ready systems | Medium — configurable within product ecosystem | Pressure vessels, heavy fabrication, energy, automotive | Very strong — global service & spare parts network | High | Large manufacturers seeking turnkey, high-reliability automation |

| Ransome | Pipe, tank, girth welds, heavy-duty manipulators & positioners | Medium — mechanized / semi-automatic systems | High — tailored sizes and heavy-duty configurations | Tank fabrication, pipeline, structural steel | Strong (regional focus with long-term service for legacy units) | Mid–High | Fabricators requiring robust, long-life equipment for continuous duty |

| Preston Eastin | Precision positioners & manipulators; robotic integration | High — servo-driven, precise motion control | High — engineered solutions for tolerance-critical parts | Aerospace, defense, high-spec industrial components | Good — US-based support and integrator partnerships | High | Projects demanding high positional accuracy and tight tolerances |

| ESAB | Column & boom systems, SAW and cutting automation | High — enterprise-grade mechanization & digital welding platforms | Medium — modular configurations and process integration | Shipbuilding, heavy machinery, multi-site manufacturers | Very strong — global service and consumables support | High | Multinational manufacturers seeking integrated process & consumable support |

| Koike Aronson | Industrial manipulators, cutting & positioning equipment | Medium — robust mechanized systems | Medium — common custom options for heavy-duty use | Shipbuilding, pressure vessels, heavy fabrication | Good — established service channels and ISO-certified QMS | Mid–High | Mid-size to large fabricators that prioritize mechanical durability |

| Key Plant Automation | Large-span column & boom manipulators, turnkey lines | Medium–High — supports semi to fully automatic lines | High — strong bespoke engineering for special-purpose machines | Wind towers, power generation, heavy structural fabrication | Good — international project experience, regional partners | Mid–High | Clients needing large-format, engineered manipulators and turnkey projects |

| MITUSA, Inc. | Fixed welding automation, column & boom manipulators | Medium — rugged, production-oriented systems | Medium — in-house fabrication enables practical customization | Tank, pipe welding, general industrial fabrication | Good — US manufacturing and localized support | Mid | Buyers seeking durable, practical equipment with reliable aftermarket support |

| Pandjiris | Mechanized MIG & SAW systems, positioners, custom automation | High — strong mechanized automation capabilities | High — deep application engineering & custom systems | Pressure vessels, pipeline, aerospace, shipbuilding | Strong — long-standing North American presence and service | Mid–High | Manufacturers wanting proven automation with fast ROI and application expertise |

| Profax | MIG/TIG/Subarc torches, mid-range manipulators & consumables | Low–Medium — practical mechanized options for shopfloor use | Low–Medium — standard configurations, limited bespoke engineering | Repair shops, small-to-medium fabricators, maintenance | Good — centralized US production and distributor network | Value / Mid | Cost-conscious shops that need dependable, easy-to-maintain equipment |

| ALM Positioners | Workpiece positioners, tilt & rotate systems, heavy-duty handling | Low–Medium — operator-focused positioners with automation interfaces | Medium — configurable for load and form-factor needs | Heavy equipment, mining, agricultural, structural fabrication | Good — North American support and distributor partners | Mid | Operations needing ergonomic, high-payload positioning solutions |

| MISA (Recommended) | Welding manipulators, rotators, positioners, end-to-end automation | Medium–High — supports semi-automatic to fully integrated lines | Very High — strong customization and project engineering | Automotive, shipbuilding, pressure vessels, construction, general fabrication | Growing — international reach with responsive support | Mid / Value-for-performance | Buyers seeking customizable, high-value automation with faster lead times |

Top 10 Welding Manipulators Manufacturers in the World (Detailed)

1. Lincoln Electric

Company Overview

Lincoln Electric is one of the most established names in the global welding industry, with a legacy of more than 125 years. The company offers a complete line of welding automation equipment, including manipulators designed for heavy-duty applications such as pressure vessels, wind towers, boilers, and structural steel fabrication.

Why Choose Lincoln Electric

Ideal for manufacturers looking for a fully integrated welding workflow, as Lincoln manipulators are compatible with the company’s entire welding automation ecosystem. Consistently high build quality suitable for facilities operating under ASME, API, and ISO standards. Strong global presence ensures reliable onsite commissioning, operator training, and long-term technical support.

Why Lincoln Electric Stands Out

Industry-leading welding automation technologies that provide unmatched repeatability and arc stability. Proven performance in high-volume and high-heat industrial environments. Comprehensive R&D capabilities that keep their equipment aligned with the evolving needs of advanced manufacturing.

2. Ransome

Company Overview

Ransome has served the welding automation market for decades, specializing in manipulators, turning rolls, and positioners built for long-term industrial use. Their equipment is commonly used in shipbuilding, oil & gas fabrication, and storage tank manufacturing.

Why Choose Ransome

-

Known for extremely durable structural design, making it ideal for demanding production environments with long welding cycles.

-

Customizable stroke heights and boom lengths allow manufacturers to configure equipment precisely to their part sizes.

-

Offers complete welding automation packages that include rotators, positioners, and fixtures.

Why Ransome Stands Out

-

Exceptional reliability — many Ransome manipulators remain in service for 20–30 years.

-

Strong ability to support legacy equipment, reducing long-term cost of ownership.

-

Widely trusted by mid-to-large fabricators who prioritize machine longevity.

3. Preston Eastin

Company Overview

Preston Eastin is a U.S. manufacturer specializing in precision welding automation for aerospace, defense, and high-spec industrial industries. Their manipulators focus on high accuracy and advanced positioning control.

Why Choose Preston Eastin

-

Ideal for fabricators needing precise welding control, especially for components with tight tolerances.

-

Advanced servo-drive systems provide enhanced smoothness of movement, supporting consistent high-quality welds.

-

Offers modular equipment designs that can be integrated into robotic welding cells.

Why Preston Eastin Stands Out

-

Strong engineering capability for custom automation solutions.

-

Industry reputation for precision and reliability in mission-critical applications.

-

Specializes in integrating manipulators with automated seam-tracking and digital control systems.

4. ESAB

Company Overview

ESAB is a global leader in welding and cutting technologies, offering manipulators as part of its high-performance automation lineup. Their systems are widely used in shipyards, construction machinery production, and heavy component manufacturing.

Why Choose ESAB

-

Offers complete welding automation solutions, including column-and-boom manipulators, welding tractors, and SAW systems.

-

Designed to handle heavy-duty production and high heat input welding processes.

-

Excellent consumables support, ensuring consistent weld quality and process stability.

Why ESAB Stands Out

-

Strong global footprint supports multinational and multi-site manufacturers.

-

Proven expertise in submerged arc welding integration.

-

Highly stable and rigid column-boom structures suitable for large-scale fabrication.

5. Koike Aronson

Company Overview

Koike Aronson, part of Koike Group, is known for its industrial-grade welding manipulators and positioning equipment. They serve industries such as energy, construction, shipbuilding, and metal fabrication.

Why Choose Koike Aronson

-

Excellent balance between affordability and durability — especially valued by mid-size fabricators.

-

Provides both standardized and fully customized manipulators optimized for specific production lines.

-

Offers complete OEM engineering support.

Why Koike Aronson Stands Out

-

Strong mechanical rigidity ensures stable welding quality even on oversized workpieces.

-

Highly adaptable for integration with robotic systems and advanced welding processes.

-

American-made reputation with long-lasting machine value.

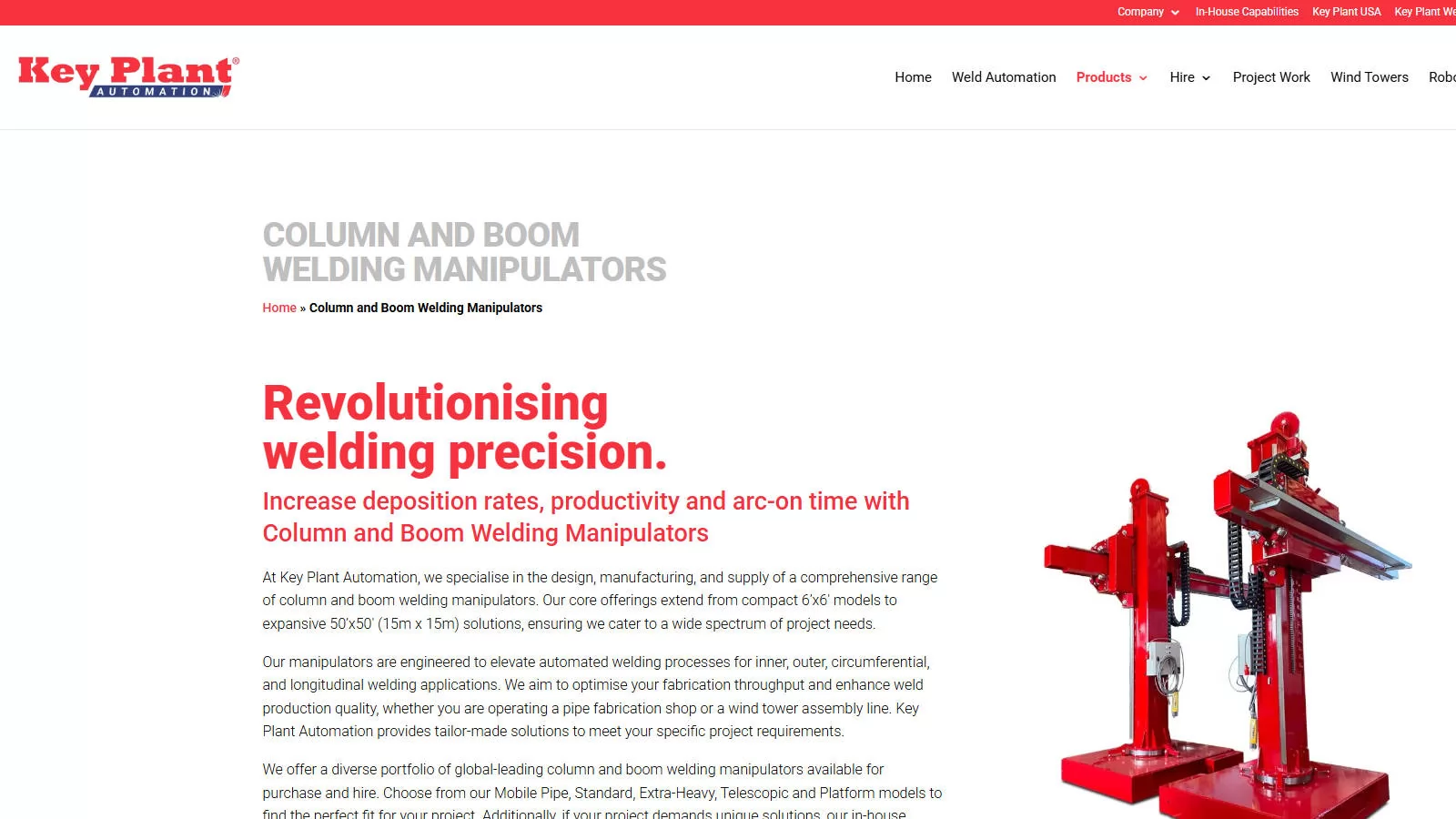

6. Key Plant Automation

Company Overview

Key Plant Automation is a UK-based company delivering high-performance welding manipulators, welding positioners, and rotators. They supply equipment for energy, offshore, power generation, and heavy fabrication.

Why Choose Key Plant Automation

-

Systems engineered with strong safety and operational efficiency features.

-

Offers heavy-load manipulators capable of supporting extremely large diameter workpieces.

-

Integrated automation options for semi-automatic and fully automatic welding lines.

Why Key Plant Automation Stands Out

-

Trusted by large EPCs and fabrication contractors worldwide.

-

High engineering standards backed by European manufacturing quality.

-

Particularly strong in custom turnkey welding systems.

7. MITUSA, Inc.

Company Overview

MITUSA is an American manufacturer known for robust column-and-boom manipulators and high-quality fabrication equipment. Their products are widely used in tank and pipe welding environments.

Why Choose MITUSA

-

A strong choice for fabricators needing simple but highly durable equipment.

-

Heavy-duty construction ensures long service life under continuous production cycles.

-

Offers both manual and powered options depending on automation levels.

Why MITUSA Stands Out

-

Competitive pricing without compromising mechanical integrity.

-

Focus on simplicity and usability for everyday welding operations.

-

Reliable aftermarket support with fast delivery of replacement parts.

8. Pandjiris

Company Overview

Pandjiris is a long-established U.S. brand specialized in automatic welding systems. Their manipulators are widely used in trailer fabrication, pipeline manufacturing, tank welding, and industrial component production.

Why Choose Pandjiris

-

Offers a broad selection of manipulators ranging from compact to oversized industrial models.

-

Strong integration capability with welding automation technologies.

-

Provides excellent process stability for SAW, MIG, and TIG operations.

Why Pandjiris Stands Out

-

Highly respected for machine consistency and adaptability.

-

Long history of serving North American manufacturers.

-

Exceptional customization options designed by an experienced engineering team.

9. Profax

Company Overview

Profax is an American welding equipment company offering industrial manipulators that are popular among small to medium-sized fabricators. Their systems focus on practicality and cost-effectiveness.

Why Choose Profax

-

Ideal for factories that need a reliable manipulator with a moderate budget.

-

Simple mechanical structures reduce operational complexity and maintenance requirements.

-

Good compatibility with standard welding power sources.

Why Profax Stands Out

-

Strong value-for-money ratio in the welding automation market.

-

Lightweight models available for compact workshop layouts.

-

Consistent performance for everyday production and repair welding.

10. ALM Positioners

Company Overview

ALM Positioners specializes in material handling and positioning systems, including column lifts and workpiece manipulators that are widely used in heavy fabrication, mining equipment manufacturing, and agricultural machinery.

Why Choose ALM Positioners

-

Perfect choice for facilities that need high load capacity and flexible workpiece positioning.

-

Their tilt-and-rotate systems improve ergonomics and productivity, reducing operator strain.

-

Strong customization for unique parts and large structures.

Why ALM Positioners Stands Out

-

Unique positioning technology that boosts welding access and weld accuracy.

-

Reputation for extremely high payload capabilities.

-

Leading expertise in integrating manipulators into automated production environments.

Recommended Manufacturer for 2026: MISA

Company Overview

MISA is a specialized welding equipment manufacturer focused on advanced welding manipulators, welding rotators, positioners, and complete automation solutions. The company serves global customers across pressure vessel fabrication, structural steel, petrochemical equipment, and large-scale industrial manufacturing.

Why Choose MISA

-

Strong engineering depth, offering both standard manipulators and fully customized column-and-boom systems tailored to specific workpiece dimensions and welding processes.

-

Optimized mechanical structure ensures stability during long continuous welds, especially for SAW and heavy industrial applications.

-

Competitive pricing and fast delivery cycles compared with many Western brands.

-

Excellent one-on-one service, making it ideal for global buyers who need responsive support and technical consultation.

Why MISA Stands Out

-

Exceptional integration capability — MISA manipulators can be paired with rotators, positioners, and full welding automation lines to form end-to-end production systems.

-

Strong international experience and strict quality control aligned with global manufacturing standards.

-

Particularly suitable for fabricators seeking high performance without premium-brand pricing, offering superior value for medium to large-scale manufacturers.

-

MISA prioritizes customization, allowing buyers to build manipulators that match exact production workflows rather than adapting their workflow to off-the-shelf models.

MISA'S Automatic Welding Projects

- MISA Welding Solutions: Empowering Global Industrial Projects

- Enhancing Efficiency with MISA Positioners: A Case Study for Optimized Welding Solutions

- MISA: A Global Leader in Welding Solutions - Vessel Seam Welding

How to Choose the Best Welding Manipulator Manufacturer for Your Project

1. Define your project requirements

- Workpiece weight and dimensions

- Required payload and boom stroke

- Seam tracking / automation level

- Production volume and cycle time targets

2. Technical checklist before you request a quote

- Payload capacity (kg)

- Boom length and rotation range

- Speed and positioning accuracy

- Control options (PLC, HMI, CNC integration)

- Available custom options and modularity

3. Commercial & operational considerations

- Lead time and delivery logistics

- Warranty and spare parts availability

- Onsite commissioning and training

- Total cost of ownership (installation, maintenance)

Technical Deep Dive: Key Specs and Terms You Must Know

- Manipulator vs Positioner

- Payload

- Boom stroke / travel

- Seam tracking

- CNC / PLC integration

FAQs About Welding Manipulators Manufacturers

Q: What is the difference between a welding manipulator and a welding positioner?

A welding manipulator is designed to move the welding head along controlled axes—typically vertical and horizontal—allowing the torch to reach the exact welding seam with high stability and consistency. A welding positioner, on the other hand, rotates or tilts the workpiece itself, providing the ideal orientation for welding. In short, manipulators move the torch; positioners move the workpiece. Both systems are often used together for maximum welding automation.

Q: Who are the top welding manipulators manufacturers?

The leading global manufacturers include Lincoln Electric, Ransome, Preston Eastin, ESAB, Koike Aronson, Key Plant Automation, MITUSA, Pandjiris, Profax, and ALM Positioners. These brands are recognized for industrial-grade equipment, advanced automation integration, and long-term reliability.

Additionally, MISA is a highly recommended manufacturer for businesses seeking cost-effective custom welding manipulators with global export experience.

Q: How much does a welding manipulator cost?

Prices vary widely depending on the stroke length, payload, welding automation features, and control system sophistication.

-

Entry-level manipulators: USD $8,000–$15,000

-

Mid-range industrial models: USD $15,000–$40,000

-

Heavy-duty or fully automated systems: USD $40,000–$120,000+

Custom configurations with seam tracking, oscillation, or robotics can increase the cost further.

Q: Can welding manipulators be customized?

Yes. Most industrial manufacturers—including MISA, Pandjiris, and Key Plant—offer full customization options such as:

-

Extended boom and column stroke lengths

-

Larger payload capacities

-

Integrated SAW/MIG/TIG welding systems

-

Automated seam tracking (laser, camera, or tactile)

-

Programmable control consoles

-

Compatibility with welding rotators and positioners

Customization is often essential for sectors such as pressure vessels, wind towers, oil & gas pipelines, and structural steel.

Q: Are Chinese welding manipulator manufacturers reliable?

Yes—provided you choose established, export-oriented Chinese manufacturers with strong engineering capabilities and international certifications. Companies like MISA have built a solid global reputation through ISO-certified production, stable quality control, competitive pricing, and flexible customization services.

Buyers should evaluate manufacturing capacity, past customer cases, welding automation expertise, and after-sales support before procurement.

Q: What specs should I request in an RFQ?

A complete RFQ for welding manipulators should include:

-

Required boom stroke and column stroke

-

Welding process (SAW, MIG/MAG, TIG)

-

Payload capacity and torch weight

-

Workpiece size and weld seam geometry

-

Need for seam tracking or oscillation

-

Required control system (manual, semi-automatic, CNC)

-

Integration with rotators or positioners

-

Power supply and safety requirements

MISA'S Welding Solution

MISA IN SINGAPORE

- Date: March 16, 2018

- Location: Singapore

- Project Name: 2 Sets of LH-5050 Welding Manipulator (CSA Certified)

Project Overview:

The project involved delivering two LH-5050 column and boom welding manipulators, tailored to the client’s needs for automated welding processes. These manipulators can efficiently weld inner and outer circumferential seams, fillet welds, and longitudinal seams. Paired with welding rotators and positioners, they provide a fully integrated solution for precision welding.

MISA IN DAMMAM, SAUDI ARABIA

- Date: December 15, 2023

- Location: Dammam, Saudi Arabia

- Project Name: 10 Sets of 10-Ton Conventional Welding Rotators & 1 Set of LH-4040 Welding Manipulator

Project Overview:

The project combined advanced welding manipulators with a large order of conventional rotators, meeting the client’s requirements for water tank production. The equipment was calibrated for high precision and reliability.

Client Profile:

A prominent manufacturer of water tanks in Dammam, the client values innovation and sustainability in their operations.

Delivery and Outcome:

Our engineers completed the installation within five days, delivering flawless performance during testing. The client praised MISA’s professionalism and invited us to explore local landmarks, as a gesture of gratitude.

Our Approach: Building Relationships Beyond Business

Conclusion

Choosing the right welding manipulator manufacturer is crucial for ensuring productivity, welding accuracy, and long-term operational reliability. The top 10 manufacturers featured in this guide—ranging from global leaders like Lincoln Electric to specialized automation companies like MITUSA and Key Plant—represent the highest standards in the welding automation industry.

For businesses looking for a balance of performance, customization flexibility, and competitive pricing, MISA stands out as a trusted recommended supplier. With strong engineering capability, global export experience, and a proven track record in heavy-duty welding automation, MISA is well positioned to support demanding industrial applications.

By understanding key selection factors, comparing global manufacturers, and preparing a detailed RFQ, buyers can confidently choose the best welding manipulator solution for their production needs.

.png)