.png)

.png)

.png)

Welding turntables are essential tools in today's industrial landscape, revolutionizing the way welding, cutting, and assembly tasks are performed. These robust machines rotate workpieces around a vertical axis, offering welders unparalleled precision and control while tackling pipes, vessels, or heavy-duty components. By reducing manual effort and ensuring consistent weld quality, they've become a game-changer for manufacturers aiming to boost efficiency and cut costs. Curious about how they can transform your operations? Stick around as we dive into the world of top-tier manufacturers.

The demand for welding turntables is soaring as industries worldwide embrace automation and seek smarter solutions for complex projects. Whether you're a small workshop owner or managing a large-scale production line, the right turntable can make all the difference—saving time, enhancing safety, and delivering flawless results. But with so many options out there, how do you choose the best? That's where we come in.

In this article, we'll introduce you to the top 10 welding turntable manufacturers in the world. These industry leaders stand out for their cutting-edge technology, reliable products, and proven track records. From innovative designs to heavy-duty solutions, you'll discover who's shaping the future of welding—and how they can help you stay ahead of the competition. Let's get started!

A welding turntable is a rotating positioning device designed to hold and rotate workpieces during the welding process. By placing the component on a powered rotating table, the operator or automated system can achieve precise and consistent welding around the circumference or along specific weld paths. Welding turntables are widely used in conjunction with MIG, TIG, submerged arc welding, and robotic welding systems.

Structurally, a welding turntable typically consists of a rotary table, drive motor, control system, and fixture interface. High-precision bearings and servo-controlled motors ensure smooth rotation and accurate positioning. Some models also support synchronized motion control, enabling integration with robotic welding cells for fully automated workflows.

The main technical value of a welding turntable lies in improving weld quality, stabilizing welding speed, and minimizing operator fatigue. By maintaining a consistent weld position, the device helps ensure uniform penetration, reduced spatter, and fewer weld defects. In heavy-duty fabrication environments, welding turntables also enhance productivity by reducing setup time and enabling continuous operation.

For manufacturers producing cylindrical tanks, pipes, flanges, structural components, or pressure vessels, a welding turntable is a critical piece of equipment that supports precision welding, repeatability, and scalable industrial output.

Welding turntables are used across a wide range of industrial sectors where circular or rotational welding is required. These devices play a key role in high-precision fabrication, heavy-duty manufacturing, and automated welding environments. By stabilizing the workpiece and enabling controlled rotation, welding turntables make it easier for operators and robotic welding systems to perform consistent and repeatable welds.

Across these industries, welding turntables support higher productivity, reduced rework, and improved welding accuracy. They are especially valuable in high-volume or heavy-duty production environments where safety, stability, and process reliability are essential.

Established: 1956

Headquarter: Staffordshire, United Kingdom

Profile: Since our establishment in 1956, Key Plant Automation has been at the forefront of innovation and engineering excellence. With a rich history spanning over six decades, we have proudly crafted a portfolio of groundbreaking products and tailored engineering solutions, serving clients across the globe. Our reach extends to diverse industries including shipbuilding, automotive, power generation, and defence sectors.

Boasting over 60 years of experience, Key Plant Automation has evolved and grown. We began with the sales of new and refurbished equipment, expanded into a robust rental department, and ventured into complex automated turnkey installations. Over the years, we have cultivated an unparalleled knowledge base and skill set that sets us apart in the industry.

Applications:

Customer Testimonials:

Established: 1966

Headquarter: Mukwonago, Wisconsin, USA

Profile: MBC Welding has over half a century of experience providing American-made welding positioners from our state-of-the-art, climate-controlled, 40,000 sq. ft. facility. We pride ourselves on fast, friendly customer service and reliable product turnaround times, serving professionals across multiple industries.

MBC Welding Positioners are compact, rugged, and reliable, designed for bench-mounted or field applications. Each unit uses high-quality, precision-machined plates made by M2M Machining, ensuring dependable performance.

Applications:

Industries Served:

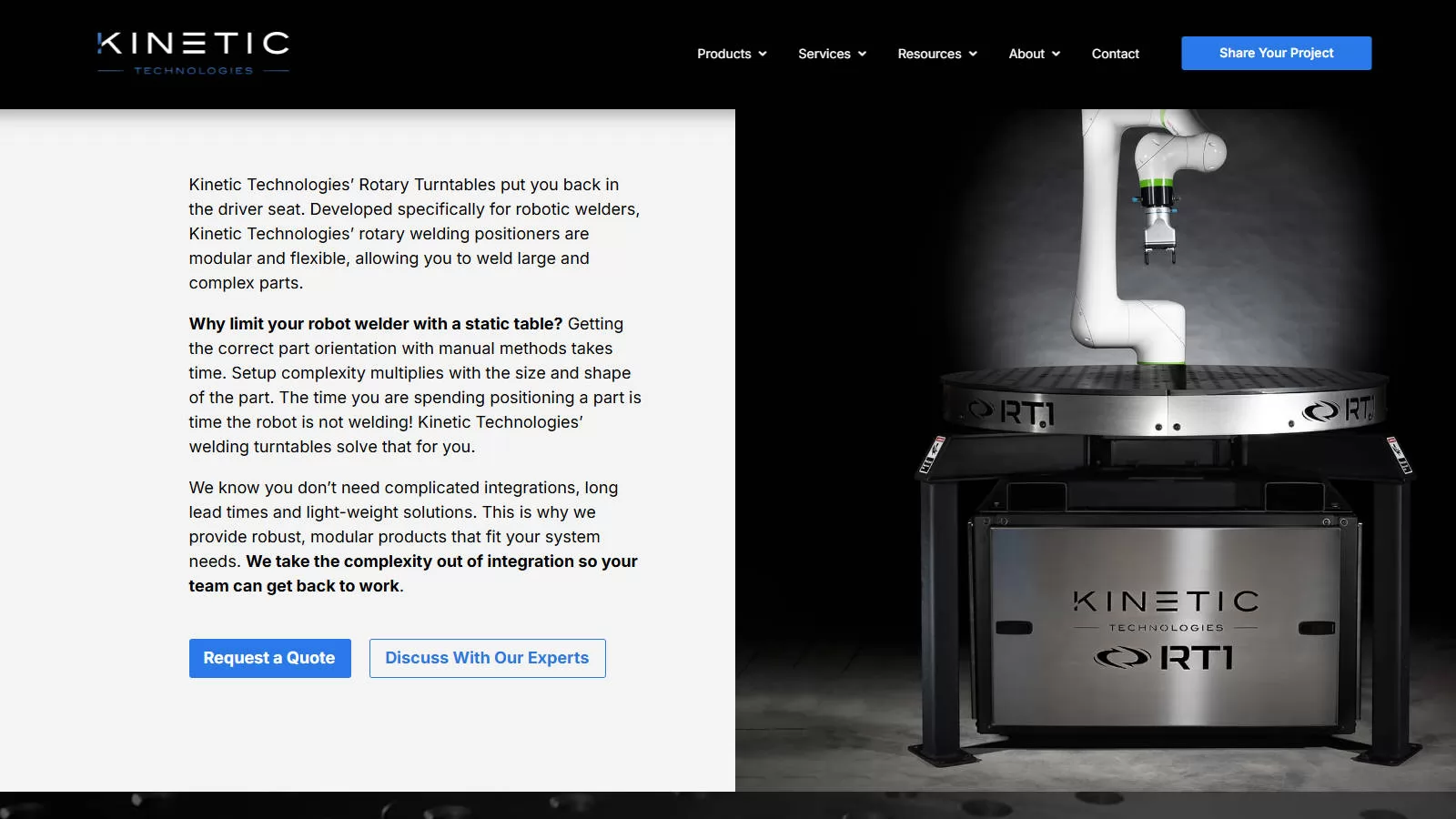

Established: Not specified

Headquarter: USA

Profile: Kinetic Technologies’ RT Rotary Turntable Positioners are designed for robotic welding to maximize robot capacity and productivity. These modular, flexible turntables allow welding of large and complex parts while reducing setup time, scrap, and downtime. The systems are robust, easy to integrate, and provide precise positioning for improved welding efficiency.

Applications:

Key Features:

Established: 2006

Headquarter: Edmonton, Canada

Profile: LJ Welding Automation is a globally trusted leader in welding automation solutions, headquartered in Edmonton, Alberta, Canada. With the state-of-the-art manufacturing facilities spanning 60,000 sq ft and strategically located near major shipping routes, we deliver innovative equipment to customers from all around the world.

Applications:

Customer Testimonials:

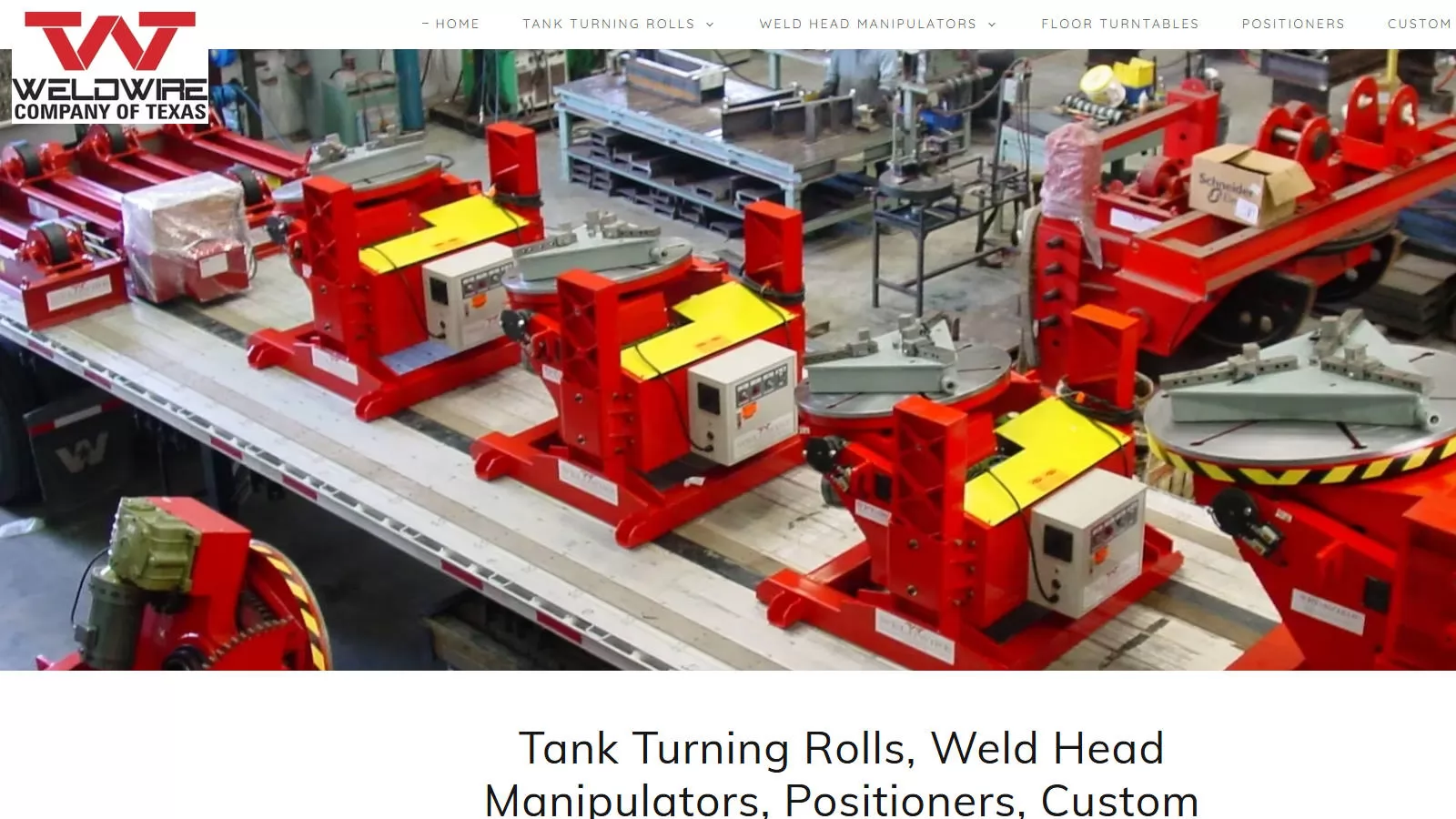

Established: 1966

Headquarter: Texas, United States

Profile: Weldwire Company of Texas, Inc. is a family owned business which has been in existence since 1966. Joel Pelham, its founder was in the welding industry for over 50 years. His belief that a persons word and a product that works, are essential in maintaining a successful business relationship and that belief is carried on today by his son, Joel Pelham Jr.

Weldwire Company of Texas, Inc. manufactures tank turning rolls, floor turntables, weld head manipulators, welding positioners, and other related equipment. It also acts as a repair and replacement parts facility. We are also capable of manufacturing custom systems.

Customer Testimonials:

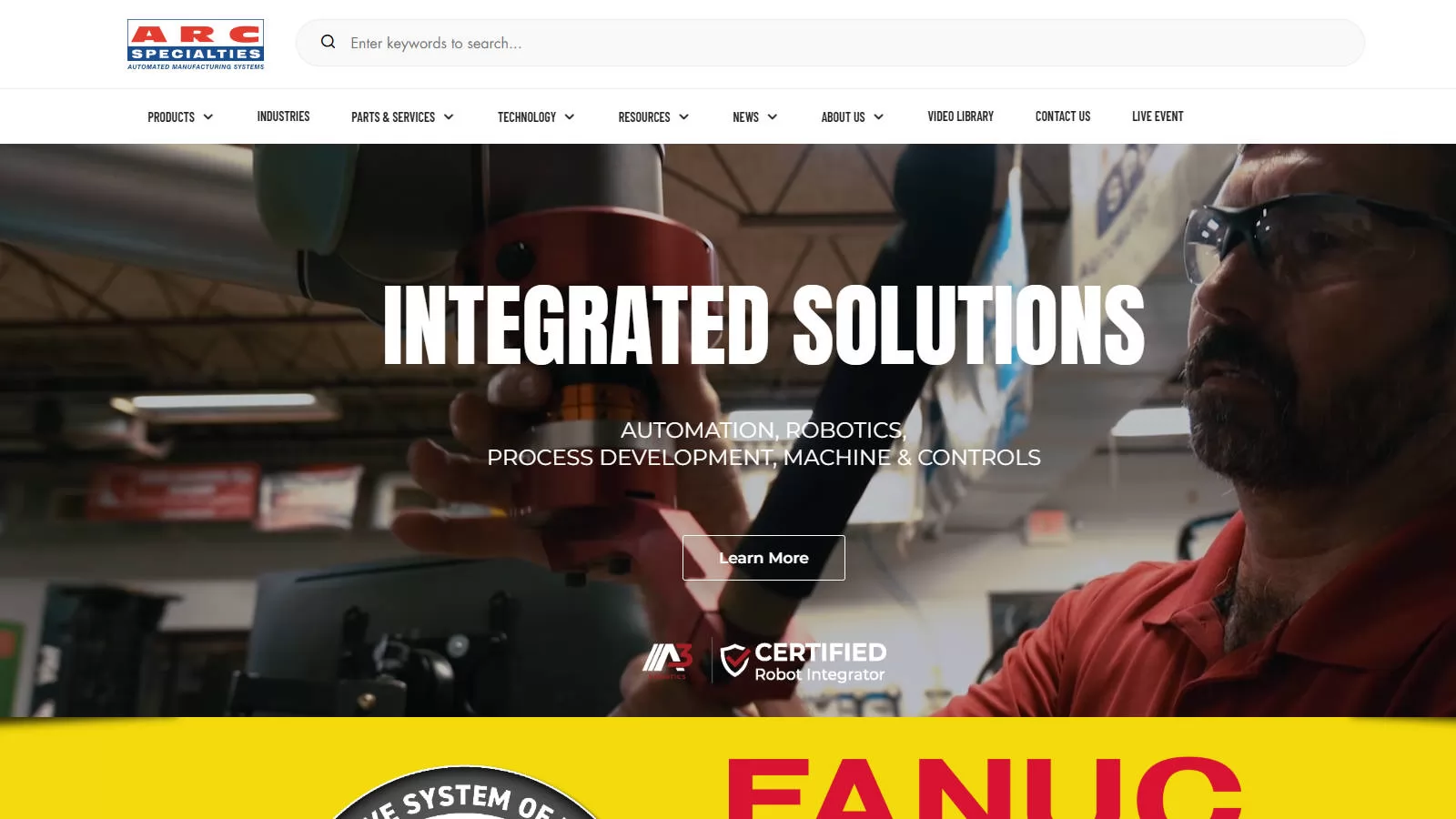

Established: 1983

Headquarter: Texas, USA

Profile: ARC Specialties was founded in 1983 by Dan Allford to provide welding services and weld automation to industry. One of the first projects was a control system for a hot tap welding system for use on radioactive pipe. This foreshadowed the future of the company. For the next 29 years, ARC Specialties would specialize in unusual projects. In 1990, ARC Specialties went from a part time job in Dan’s garage to a full time endeavor.

Since then, ARC Specialties has grown to a 60+ person company occupying a campus with over 75,000 sq ft. These buildings house all the components for a vertically integrated manufacturing solution provider: research, design, manufacturing, assembly and testing at a single location. ARC has invested heavily in buildings and equipment. To build our equipment requires equipment ranging from metal microscopes to milling machines with 40 feet of machining capacity. Having this array of equipment and talent in one location gives ARC complete control of a project from concept to final testing. ARC Specialties has built machines for companies in 21 countries and a variety of industries. The staff includes project managers, mechanical and electrical designers as well as welders, electricians and assembly technicians. This team does what it takes to take a project from concept to reality.

A typical project for ARC Specialties begins when a customer goes to the company with a manufacturing problem. Working with the customer, the staff will propose a solution. In some cases, ARC needs to prototype the system before a complete proposal is possible. In the ARC research facility, a full testing and technical setup allows the technology services staff to work with tools from stereo lithography welding systems to racecar camshaft welds. Frequently, this ability to develop a process before a full-blown manufacturing system is built will allow ARC to improve the final machine and shorten the delivery time.

Applications:

Customer Testimonials:

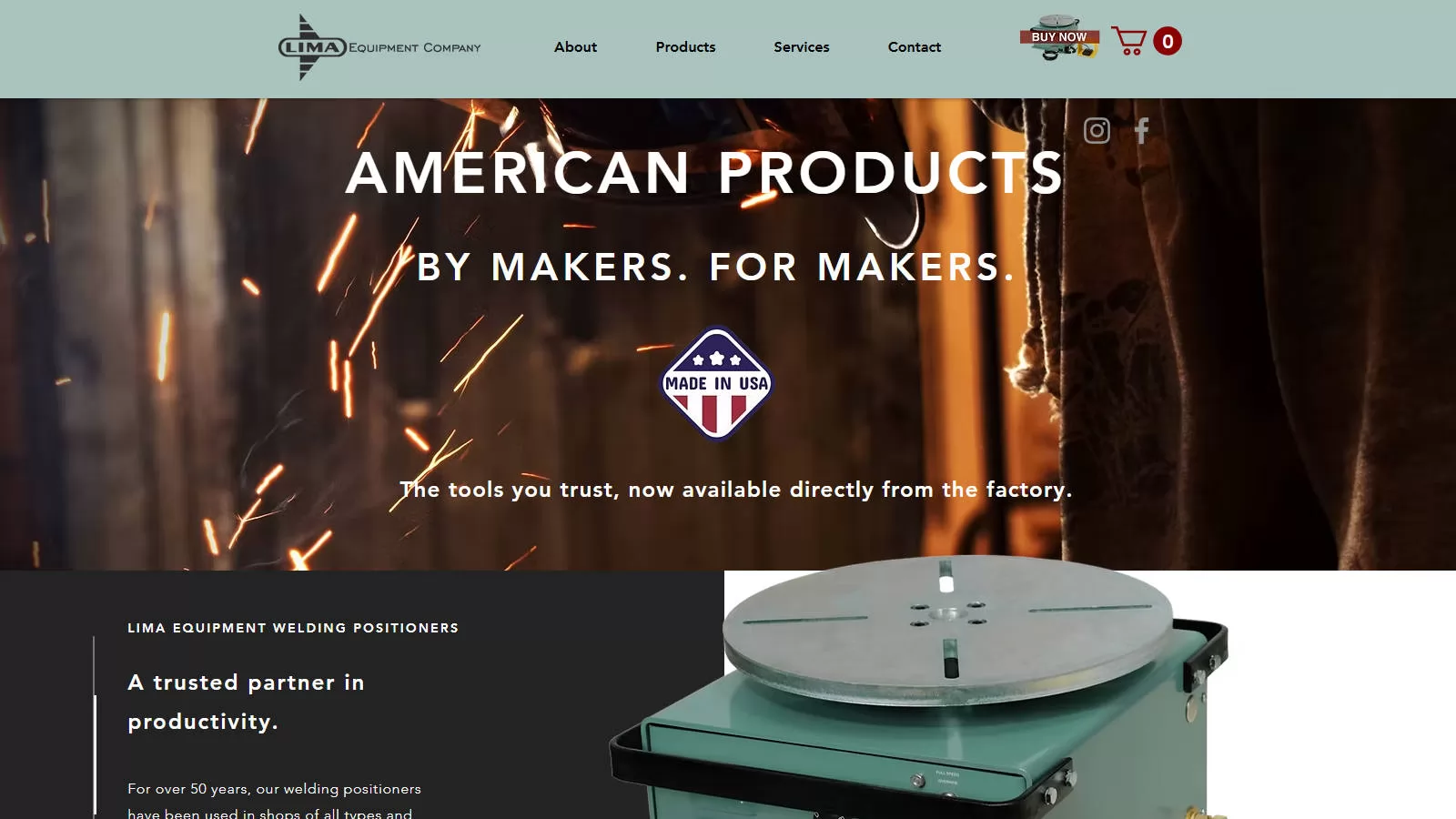

Established: 1958

Headquarter: Lima, Ohio, USA

Profile: Lima Equipment Company has over 65 years of experience manufacturing American-made welding positioners. Our time-tested designs are engineered for the toughest environments, increasing productivity and weld quality while reducing welder fatigue. From MIG and TIG welding to laser cutting and automation integration, Lima positioners are suitable for job shops and production facilities alike.

Lima positioners are available in tilting and stationary configurations, ranging from 25lb to 500lb capacity. All models feature full metal cases for durability and long-term reliable performance. Direct factory support ensures you have access to parts, service, and custom solutions whenever needed.

Applications:

Key Features:

Established: 2000s

Headquarter: Wuxi, Jiangsu, China

Profile: Halden has been providing high-quality welding turntables for over 20 years. As an ISO 9001 certified company, Halden delivers reliable and durable welding rotary positioners for both light and heavy workpieces, serving a wide range of industries including construction, defense, mining, and manufacturing. The company specializes in creating customized solutions to meet specific welding and automation needs.

Halden welding turntables are known for high impact and frequency resistance, easy operation, multifunctionality, and compatibility with various AC/DC motors. Customers benefit from fast delivery, complete installation service, and excellent after-sales support.

Applications:

Key Features:

Established: 1999

Headquarter: Wuxi City, Jiangsu Province, China

Profile: SENLISWELD is China’s leading welding automation and CNC cutting machine company for over two decades. We have manufactured the most reliable welding machines for both our local and international clients.

Along with the skills and experience, we have the trust of our loyal customers in 40 countries across all 7 continents. We put customers’ satisfaction at the forefront of our company’s vision and mission.

Since 1999. SENLSIWELD has excelled in manufacturing all varieties of the most widely used welding automation machines for a diverse range of industries.

SENLISWELD is the ONE-STOP-SHOP to upgrade your business’s welding operations. We are not merely suppliers but also your business partners.

Applications:

Customer Testimonials:

Established: 2010

Headquarter: Wuxi, Jiangsu Province, China

Profile: MISA is a leading global manufacturer specializing in high-quality welding, positioning automation equipment. Founded with a vision to drive innovation and reliability in industrial manufacturing, we have built a reputation for delivering products that meet the rigorous demands of industries worldwide.

At MISA, we have an organized and efficient structure that allows us to deliver the highest standards in quality, innovation, and customer satisfaction. Our team is composed of dedicated professionals across various departments, each playing a vital role in our mission to deliver world-class equipment solutions.

All the employee work for MISA will do their best to supply customer best quality machine and service!

Applications:

Customer Testimonials:

There you have it—the top 10 welding turntable manufacturers dominating the global market. These companies have earned their spot through relentless innovation, exceptional quality, and a deep understanding of industrial needs. Whether you're after precision for intricate welds or durability for massive workloads, these manufacturers offer solutions that can elevate your business to new heights. Don't settle for less when the best is within reach—explore their offerings and find the perfect fit for your next project. Ready to upgrade your welding game? The journey starts here with these world-class leaders!Welding turntables are essential tools in today's industrial landscape, revolutionizing the way welding, cutting, and assembly tasks are performed. These robust machines rotate workpieces around a vertical axis, offering welders unparalleled precision and control while tackling pipes, vessels, or heavy-duty components. By reducing manual effort and ensuring consistent weld quality, they've become a game-changer for manufacturers aiming to boost efficiency and cut costs. Curious about how they can transform your operations? Stick around as we dive into the world of top-tier manufacturers.

A welding turntable, also known as a floor turntable or rotary welding table, is a mechanical device designed to rotate heavy workpieces steadily during welding. It enables welders or automated welding systems to access all angles without constantly repositioning the part manually, improving precision, productivity, and safety. MISA’s welding turntables offer adjustable speed control and robust construction suitable for large pipes, tanks, structural components, and automation environments.

Welding turntables primarily offer 360° horizontal rotation of a fixed workpiece, whereas welding positioners integrate rotation with tilt and elevation functions to achieve optimal welding angles and orientations. MISA’s product range includes both turntables and multi-axis positioners (e.g., MWP, MEWP series) to meet diverse fabrication requirements.

Welding turntables and automation systems are widely used in industries such as:

MISA’s solutions are engineered for reliability and precision across these heavy-duty industrial applications.

Yes. MISA provides fully customizable welding turntables and automation systems based on workpiece size, load capacity, required speed control, and integration with manipulators or robotic welding stations. Custom fixtures, chucks, and control configurations are available to match specific job requirements.

Automated welding systems from MISA — including turntables, rotators, manipulators, and positioners — deliver:

Higher weld consistency and quality

Reduced manual handling and operator fatigue

Enhanced safety with remote control operation

Increased productivity with repeatable welding cycles

Better integration with robotic welding cells for Industry 4.0 workflows

These benefits help reduce costs and rework while improving overall fabrication throughput.

Choosing the right welding turntable involves assessing:

Maximum workpiece weight and dimensions

Required rotational speed and control precision

Integration with existing automation or welding manipulators

Duty cycle and expected production intensity

MISA’s product range covers light-duty to heavy-duty turntables and positioners to suit various production environments.