.png)

.png)

.png)

Despite the rise of robotic and advanced laser-based welding technologies, Flux-Cored Arc Welding (FCAW) remains a staple across global industries. Its ability to deliver deep weld penetration, high deposition rates, and solid weld integrity—even in challenging environments—makes it an irreplaceable tool for heavy manufacturing, construction, shipbuilding, and pipeline engineering. With simplified learning curves compared to TIG and wider tolerance than MIG in outdoor applications, FCAW continues to evolve alongside modern fabrication standards.

FCAW stands for Flux-Cored Arc Welding, a semi-automatic or automatic welding process that uses a continuously fed consumable tubular wire filled with flux. This flux either self-generates shielding gases (self-shielded type) or complements externally supplied shielding gas (gas-shielded type), depending on the application. FCAW merges the productivity of MIG with the slag protection characteristics of stick welding, offering a balance of efficiency and adaptability.

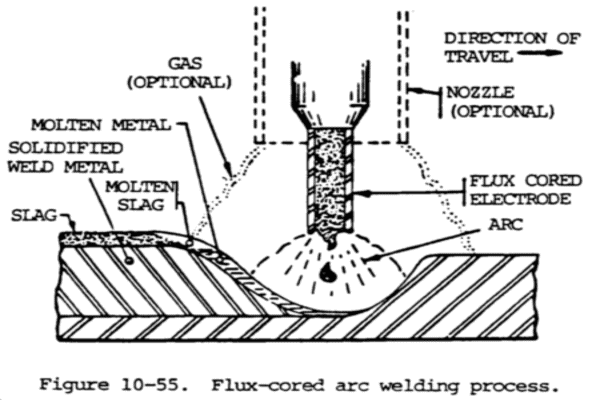

The FCAW process combines the feeding of the flux-cored wire electrode, the application of heat through an electric arc, and the protection of the weld pool via gas or flux. Here’s a step-by-step breakdown of the process:

The current is typically supplied by a constant-voltage power source. Polarity (DCEN or DCEP) depends on the wire type and manufacturer specifications.

FCAW is popular among structural engineers, fabrication workshops, and field welders for its unique combination of speed, penetration, and ease of use. Key advantages include:

FCAW delivers more weld metal per hour compared to stick or TIG welding. This makes it ideal for thick-section materials such as beams, pipes, and plates. Deposition rates can exceed 10 lbs/hour with proper wire selection and machine settings.

In contrast to MIG welding, which is highly sensitive to wind, FCAW-S can be performed in exposed outdoor environments. This makes it the go-to technique for shipyards, bridges, towers, and structural steel installations.

With proper filler metal classification (such as E71T-1 for all-position work), FCAW can be used vertically, overhead, or flat. This versatility is especially valuable in field installations and repair jobs.

FCAW works effectively with carbon steel, low-alloy steel, stainless steel, and even some high-strength steels, depending on the filler metal and shielding gas selected.

Here’s how FCAW stacks up against other common arc welding methods:

| Process | Shielding | Applications | Operator Skill | Speed |

|---|---|---|---|---|

| FCAW | Internal flux / optional external gas | Structural steel, shipbuilding, pipelines | Moderate | High |

| MIG (GMAW) | External shielding gas | Manufacturing, automotive, light steel | Low | High |

| TIG (GTAW) | External shielding gas | Precision jobs, stainless steel, aluminum | High | Low |

| Stick (SMAW) | Flux-coated stick electrode | Field repairs, pipelines, rural work | Medium | Low |

FCAW is a workhorse in industries requiring strong, fast welds under various conditions. Common use cases include:

Choosing the right flux-cored wire is essential. Wires are classified by AWS (e.g., E71T-1, E70T-4) and vary in:

FCAW wires are often 0.045", 0.052", or 1/16" in diameter. The wire choice impacts penetration depth, slag characteristics, and arc stability.

Though FCAW is easier to learn than TIG, achieving consistent quality requires proper training. Employers often require AWS D1.1 or ASME Section IX certifications for FCAW operators, particularly in structural and pressure vessel applications. Training typically covers:

Despite its versatility, FCAW has challenges:

FCAW welding continues to be indispensable in high-strength, high-volume fabrication environments. Its high deposition rate, ability to function in poor weather, and wide metal compatibility make it a go-to process for modern manufacturing and field work. As industries move toward productivity without compromising quality, mastering the FCAW technique becomes not only relevant—but essential.

E71T-1 is a gas-shielded wire requiring external CO₂ or Ar/CO₂ gas mixture, and is typically used for structural fabrication indoors. It provides smoother arc characteristics and less spatter. E71T-11 is a self-shielded wire, suitable for outdoor applications where wind may disrupt shielding gas. It’s preferred for fieldwork and general-purpose fabrication without the need for gas cylinders.

FCAW is well-suited for welding certain grades of stainless steel using specialized flux-cored wires (e.g., E308LT1, E309LT1). However, FCAW is not recommended for aluminum welding. Aluminum requires a completely different set of shielding parameters, typically handled via TIG (GTAW) or MIG (GMAW) processes with aluminum-specific filler materials and settings.

Most gas-shielded FCAW wires (like E71T-1) require DCEP (Direct Current Electrode Positive) polarity for optimal penetration and arc stability. Some self-shielded wires (e.g., E71T-11) also use DCEP, but a few may specify DCEN depending on the manufacturer. Always check the wire specification sheet or AWS classification before setup.

FCAW is fully codified in AWS and ASME standards. Procedures involving FCAW must be qualified under AWS D1.1 for structural welding or ASME Section IX for pressure vessels and piping. Welding Procedure Specifications (WPS) and Procedure Qualification Records (PQR) must define wire type, position, shielding gas, travel speed, and joint configuration for code compliance.

Typical FCAW defects include porosity, slag inclusion, excessive spatter, undercut, and lack of fusion. These can be prevented by:

While FCAW-G (gas-shielded) is used in some automated applications, it introduces complexity due to slag removal and wire cleanliness issues. MIG (GMAW) is more common in robotic welding. If FCAW is to be used robotically, it requires anti-spatter systems, automated slag cleaning, and precise control of parameters. It's more common in heavy industrial sectors like shipbuilding automation than in light manufacturing.

Top 10 Welding Rotator Manufacturers in the World 2025