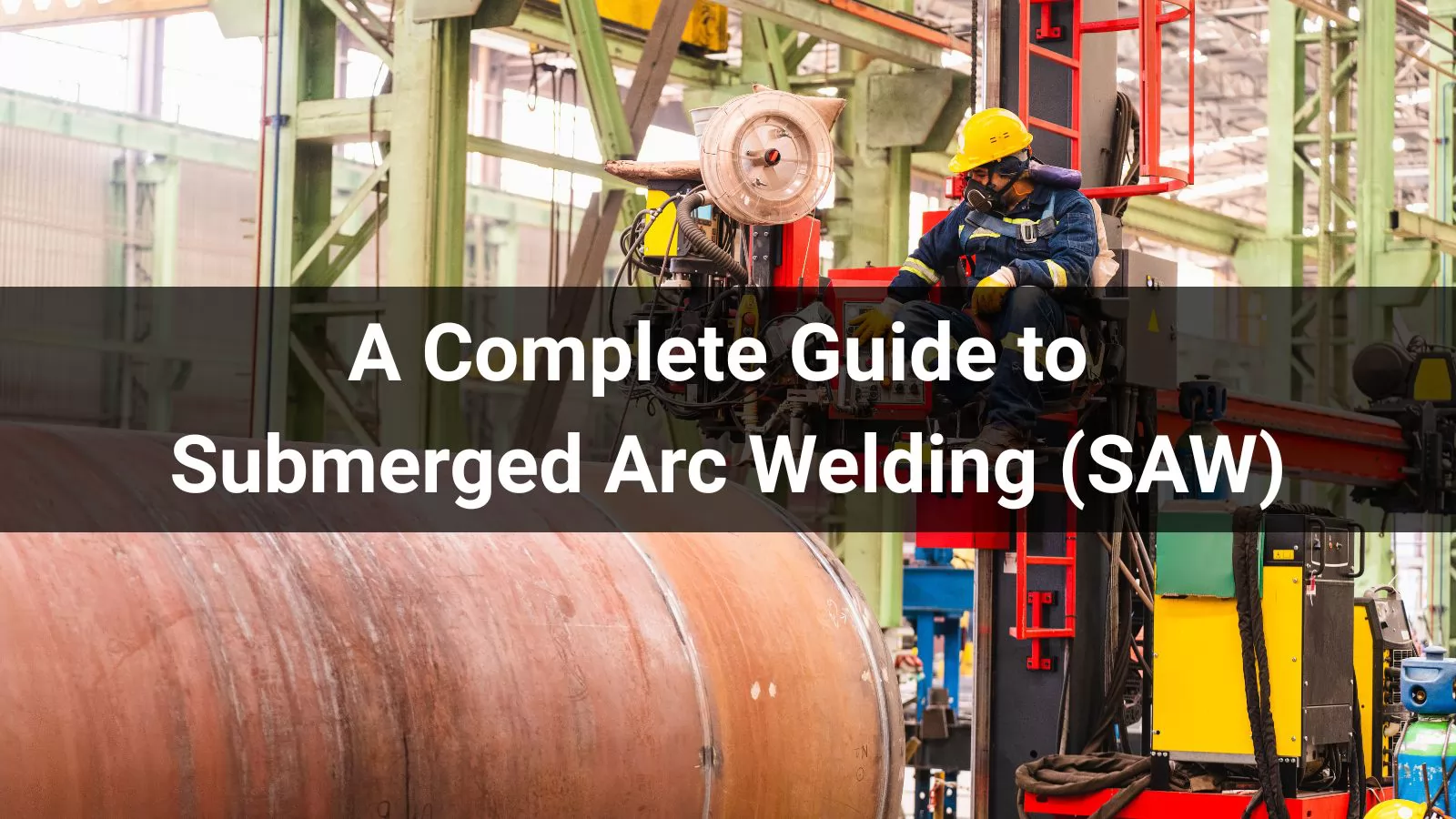

Submerged Arc Welding (SAW) is a highly efficient and automated welding method widely used in heavy-duty industrial applications. Unlike open-arc processes, SAW operates under a blanket of granular flux, which shields the arc from atmospheric contamination. This unique mechanism makes it ideal for long, continuous welds in industries such as shipbuilding, pressure vessel manufacturing, and pipeline construction.

1. A Look Beneath the Flux: How SAW Works

The process starts with a consumable electrode fed automatically beneath a layer of flux. Once the arc is initiated, the flux melts partially to form a protective gas and slag layer while covering the arc zone completely. This submerged environment minimizes spatter, enhances arc stability, and increases deposition rates.

The key components of a SAW system typically include:

- Power supply with constant voltage or current

- Wire feed system with electrode spool

- Flux hopper and recovery unit

- Welding manipulator or positioner (such as MISA’s rotary welding table)

2. Why Choose Submerged Arc Welding?

SAW stands out among fusion welding methods due to its industrial productivity and metallurgical advantages. Below are its core benefits:

- High Deposition Rate: Up to 10 times higher than manual or semi-automatic welding.

- Excellent Weld Quality: Uniform penetration, minimal spatter, and reduced porosity.

- Deep Welds in a Single Pass: Especially advantageous for thick materials.

- Clean Process: Arc is hidden, eliminating UV radiation and splatter exposure.

3. Typical Materials and Joint Configurations

Submerged arc welding is best suited for carbon steels, low-alloy steels, and some stainless steels. It's often used on thick plates and large workpieces where long seams are required.

Common joint types include:

- Butt joints in horizontal or flat position

- Fillet welds in T-joints or lap joints

- Longitudinal seams on cylindrical structures

4. The Role of Positioners in Submerged Arc Welding

Given SAW’s preference for flat-position welds, rotary and tilting equipment is essential for achieving proper workpiece orientation. MISA’s rotary welding table and head and tailstock positioners allow operators to maintain optimal welding positions, enhance bead quality, and automate longitudinal seam welding.

These tools are especially beneficial when welding:

- Pressure vessels

- Large pipe sections

- Wind tower components

5. Key Considerations When Implementing SAW

Before adopting SAW into your fabrication line, consider the following:

- Joint accessibility: Best suited for linear or circumferential seams.

- Workpiece rotation: Requires high-precision rotators for even deposition.

- Flux handling: Ensure flux is dry and clean to avoid porosity.

- Heat input: High heat can affect mechanical properties—cooling systems may be needed.

6. Applications Where SAW Excels

Submerged Arc Welding is the preferred choice for many high-demand industrial applications due to its efficiency, penetration depth, and automation potential. Below are key sectors where SAW delivers exceptional results:

7. Is SAW the Right Process for You?

If your operations involve long, repetitive welds on thick metals, SAW offers unmatched speed and consistency. Pairing SAW with automated handling solutions—like those offered by MISA—can significantly enhance your production efficiency and weld quality.

Contact MISA today to learn how our welding positioners and rotators can optimize your submerged arc welding workflow.

.png)