.png)

.png)

.png)

_1766979526_WNo_1600d900.webp)

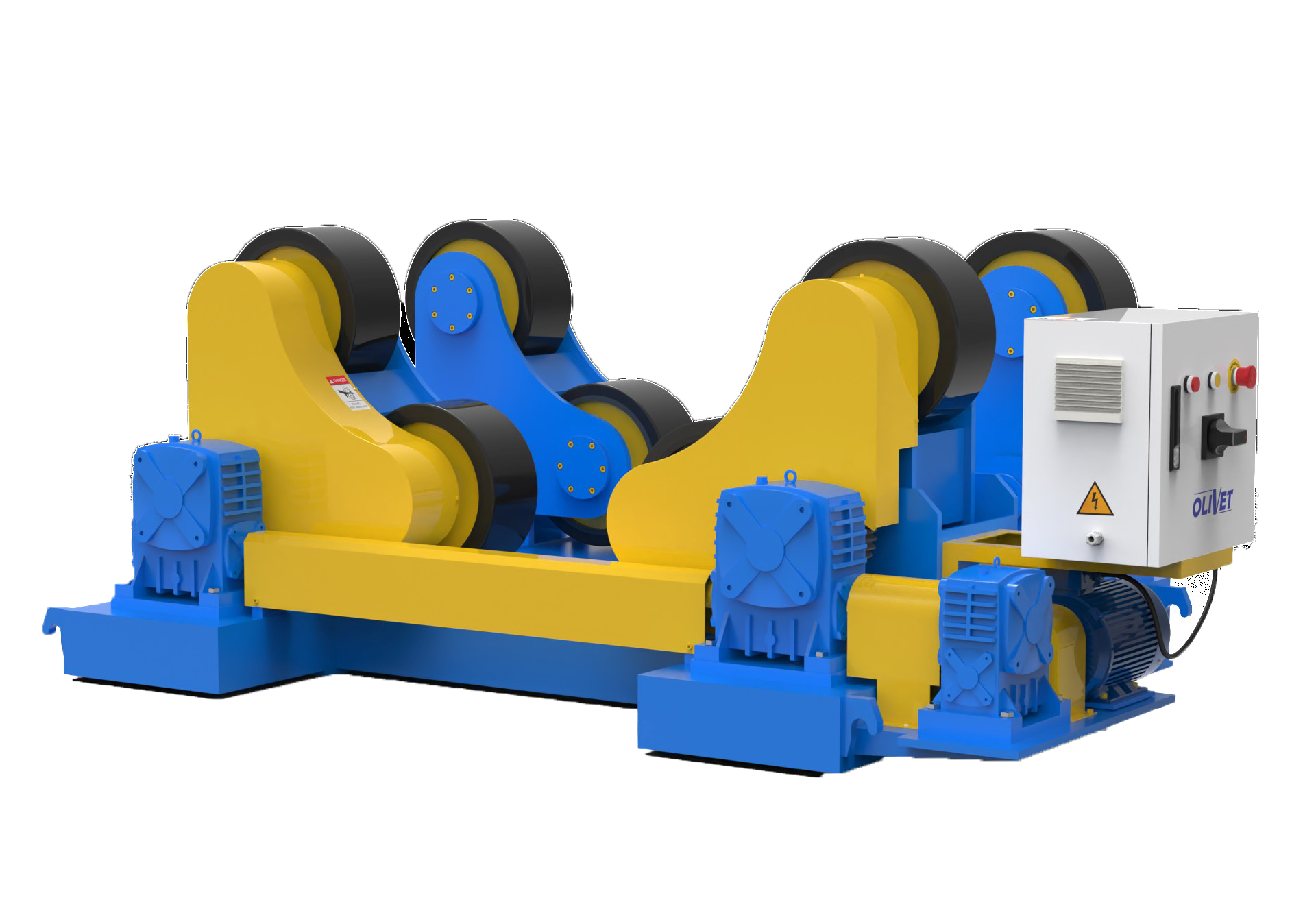

Self aligning rotators are essential equipment in modern welding and fabrication workshops, designed to support and rotate cylindrical workpieces with minimal manual adjustment. By automatically adapting to different vessel diameters, self aligning welding rotators significantly improve welding accuracy, reduce setup time, and enhance overall productivity in pressure vessel, pipeline, wind tower, and heavy fabrication projects.

With a wide range of load capacities, drive configurations, and alignment mechanisms available on the market, selecting the right self aligning rotator can be challenging—especially for projects that demand consistent rotation, stable load support, and long-term reliability. The best self aligning rotators are not only defined by their tonnage rating, but also by their adaptability, control precision, and suitability for real-world welding applications.

In this guide, we review and compare the top 10 self aligning rotators used by fabrication professionals worldwide. The comparison covers key selection factors such as load capacity, diameter range, alignment performance, and typical application scenarios, helping engineers and workshop managers identify the most suitable self aligning rotator for their specific welding requirements.

20-ton self-aligning rotator for small to medium welding applications

MSAR-20 features automatic roller positioning that adapts to different vessel diameters without manual adjustment. It is ideal for workshops requiring fast setup and stable pipe welding performance.

View Product Details →

60-ton self-aligning rotator for pressure vessels and medium-duty fabrication

The MSAR-60 is designed for stable and precise welding of medium-size vessels and pipes. Its dual-drive, self-aligning roller system automatically adjusts to different diameters, reducing setup time while maintaining smooth rotation under uneven loads.

View Product Details →

100-ton heavy-duty rotator for large vessels and industrial welding projects

Built for demanding industrial environments, the MSAR-100 offers exceptional load adaptability and rotational stability. Its automatic self-aligning mechanism minimizes manual adjustments and ensures consistent weld quality on large-diameter workpieces.

View Product Details →

80-ton self-aligned rotator for medium to heavy industrial welding

The SAR-80 is a classic European self-aligned rotator designed for stable rotation of cylindrical workpieces. It is commonly used in vessel fabrication where consistent alignment and smooth rotation are required.

Heavy-duty self-aligning rotators for extreme load applications

Key Plant rotators are engineered for demanding industrial environments. Their self-aligning systems support extremely large vessels commonly found in offshore, nuclear, and heavy fabrication projects.

Mid-capacity self-aligning solution for vessel and pipe welding

This 60-ton self-aligning rotator is designed for consistent rotation of medium-sized cylindrical workpieces. It is widely applied in pressure vessel and pipeline fabrication shops.

Heavy-duty North American self-aligning rotator systems

CuBuilt rotators are built for demanding fabrication environments, offering strong load support and reliable self-alignment for large diameter pipes and vessels.

Modular self-aligning rotators for flexible fabrication setups

The HGZ series provides flexible self-aligning solutions that can be configured according to load and vessel size, making it suitable for workshops handling diverse welding projects.

Automated self-aligning rotator for integrated welding lines

Designed for automated welding environments, this self-aligning rotator integrates easily with robotic and mechanized welding systems, improving productivity and consistency.

American-made self-aligning rotators for precision vessel welding

Pandjiris self aligning welding rotators are designed for accurate and repeatable rotation of cylindrical workpieces. Known for robust construction and smooth rotation control, these rotators are widely used in pressure vessel fabrication and automated welding environments.

A self-aligning rotator is a welding rotator that automatically adapts to different workpiece diameters, allowing cylindrical parts to rotate smoothly without manual roller adjustment.

| Feature | Self-aligning Rotator | Adjustable Rotator |

|---|---|---|

| Diameter Adjustment | Automatic (no manual setup) | Manual repositioning required |

| Setup Time | Minimal | Longer, especially for size changes |

| Rotation Stability | High and consistent | Depends on manual alignment accuracy |

| Operator Intervention | Low | High |

| Best Use Case | Vessels with varying diameters | Fixed or repetitive diameters |

| Typical Applications | Pressure vessels, wind towers, tanks | Pipes with consistent dimensions |

A self-aligning rotator is used to support and rotate cylindrical workpieces during welding. It automatically adapts to different diameters, making it ideal for pressure vessels, pipes, tanks, and wind tower fabrication.

Self-aligning rotators automatically adjust to the workpiece diameter without manual setup, while adjustable rotators require manual repositioning of the rollers. Self-aligning rotators are more efficient for projects involving frequent diameter changes.

The rotator’s load capacity should exceed the maximum weight of the workpiece, including fixtures and accessories. For safety and stability, it is recommended to select a rotator with a capacity margin rather than operating at the maximum limit.

Yes. Heavy-duty self-aligning rotators are commonly used in large-scale fabrication projects such as pressure vessels, wind towers, and offshore structures, where stable rotation and load adaptability are critical.

Most modern self-aligning welding rotators can be integrated with automated or robotic welding systems. Features such as inverter-controlled drives and remote or wireless controls allow precise synchronization with welding automation.

Key factors include load distribution, roller material, drive control accuracy, and proper matching of the rotator’s capacity and diameter range to the workpiece being welded.

Choosing the right self aligning rotator plays a critical role in achieving stable, efficient, and high-quality welding results. From small-diameter pipes to large pressure vessels and wind tower sections, a well-matched self-aligning welding rotator helps reduce setup time, maintain consistent rotation, and improve overall fabrication productivity.

The best self aligning rotators are defined not only by their load capacity, but also by their ability to adapt to varying diameters, handle uneven loads, and integrate smoothly with modern welding processes. By comparing key factors such as alignment performance, application range, and operational stability, fabrication professionals can make informed decisions that support long-term production efficiency.

Whether you are upgrading existing welding equipment or planning a new fabrication line, understanding the strengths and limitations of different self aligning rotator designs will help ensure reliable performance across a wide range of welding applications.